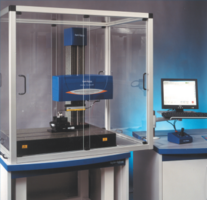

Stylus Instrument / Profilometer PGI1200

Examples of use:

- Examination of the surface topography even on slightly curved surfaces

- 3D-mappings for the determination of waviness and roughness

- Creation and evaluation of surface profiles of workpieces

Device configuration:

Horizontal Performance

- travers length - X Max / Min: 200mm / 0.1mm (7.9in / 0.004in)

- measuring speeds: 0.1mm/s, 0.25mm/s, 0.5mm/s & 0.1mm/s (0.004in/s, 0.01in/s, 0.02in/s & 0.04in/s)

- traverse speeds: 0.1-10mm/s (0.004-0.39in/s)

- data sampling interval in X: 0.125µm over 200mm length (5µin over 7.9in length)

- maximum number of data points: 1,600,000

- straightness error [Pt]: 125nm/200mm (10µin/7.9in)

- datum correction: standard

Vertical Performance

- nominal measuring range (Z): 12.55mm (60mm stylus arm) (0.49in [2.36in])

25mm (120mm stylus arm) (0.98in [4.72in]) - resolution (Z) ³ : 0.8nm @ 12.55mm range (0.03µin @ 0.49in range)

- range to resolution ratio ³ : 15,625,000 : 1

- stylus arm length, tip size, force: 66mm arm, 2µm radius conisphere diamond styling, 1mN force, 122mm arm, 0.5mm radius ball, 20mN force

- Z axis nonlinearity: (0.07 + 0.03 Z [mm]) µm (3 + 30 Z [inches]) µin - after calibration 4

- repeatability of Z axis indication (flat surface - diamond stylus): 0.15µm (6.1µin) 5

- repeatability of Z axis indication (curved surface - diamond stylus): 0.16µm (6.3µin) 5

- repeatability of Z axis indication (curved surface - ball stylus): 0.12µm (4.5µin) 5

- Four-Point Measurement of Resistance

- Abrasion Resistance

- Flame Treatment Units

- CGME – Controlled Growth Mercury Electrode

- Digital Microscope

- ECMC – Electrochemical MiniCell

- EDX-Analysis

- Planar Plasma Sources

- Fluorination

- FTIR Spectroscopy

- GDP-C

- Cross-Cut Tester

- Grey Scale Measurement

- Gravimetric Titrator – Alino®

- Hardness Tester

- Hardness and Micro Hardness Testing

- Infrared Camera - Vario THERM

- Infrared Thermometer (Pyrometer)

- Jet Plasmas

- Confocal Microscope

- Laboratory Electroplating

- Lacquer Testing Device Carving Graver

- Conductivity Measurement for Non-Ferrous Metals

- Optical Microscope Leica DMi8 C

- Mastersizer

- Optical Emission Spectrometer

- pH Value Determination

- pH/Conductivity Meter

- Plasma Polymerization

- Potentiostat / Galvanostat / ZRA

- Contact Angle Measuring Instrument

- Scanning Electron Microscope (SEM)

- Atomic Force Microscope (AFM)

- Roughness

- Rheometer MCR 301

- Rheometer MCR 502 TDR

- Scratch Hardness Tester

- X-Ray Fluorescence Unit Fischerscope

- X-Ray Photoelectron Spectrometer XPS

- Admittance

- Coating Thickness Gauge MiniTest 4100

- Coating Thickness Gauge Quint Sonic

- Sol-Gel Unit

- Spectral Ellipsometer SE850

- Sputter Technology

- Stylus Instrument / Profilometer Alpha-Step D-600

- Stylus Instrument / Profilometer PGI1200

- Thermal Evaporation

- Universal Testing Machine

- UV/VIS Spectrometer

- UV-VIS Spectroscopy

- Wear Test

- Videoextensiometer RTSS

- Xenon Arc Test

- Zeta Potential Measurement