Projects funded by the Free State of Thuringia

Here you will find an overview of current projects of INNOVENT, which were funded by the Free State of Thuringia. The projects supported by the Free State of Thuringia were co-financed by funds of the European Union within the framework of the European Regional Development Fund (EFRE) or the European Social Fund (ESF).

2022 WIN 0048: The subject of the contract includes the provision of various devices and techniques for the Smart Composites project, which will enable the development of new intelligent composite materials, flexible and efficient product systems, individualized and highly specialized materials as well as additional powerful technologies for their production and study. Some of these are upgrades to existing systems. A tensiometer is to be updated and equipped with additional modules. Furthermore, cuvettes for upgrading an existing IR spectroscopy system, a grinding system for a Dispermat and a digital camera for a microscope are to be purchased. In addition, for the Smart Composites project, an NMR, vacuum drying cabinets, RF plasma chamber and evaporator for Teflon, ozone generator, abrasion and abrasion tester, UV hardening device, laboratory AirCoat and a UV/VIS spectrometer as well as preparation technology ( sheet metal shears, precision scales, flake ice makers, pumps, structure preparators) are invested.

Client: INNOVENT e.V.

Contractor: various

Type of procedure: Open procedure

Type of service: investment

Scope of the service: €450,000

Period of performance: 01/01/2023 - 09/30/2023

Aim of the project:

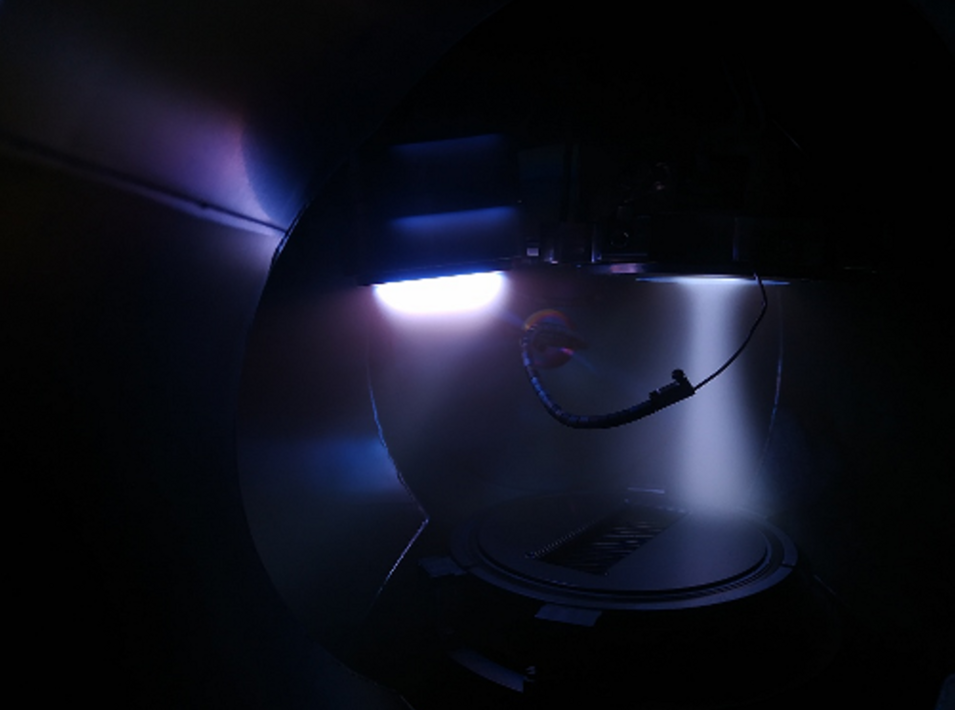

The aim of the project is the development of scalable plasma-based processes (in particular dc magnetron sputtering) for the production of flat yttrium iron garnet (YIG) thin films as a base material for extremely energy-efficient magnonic data processing components in combination with conventional semiconductor materials.

Duration:

01/01/2023 – 12/31/2025

Beneficiary:

INNOVENT e.V.

Financial support: Funded by the Free State of Thuringia with funds from the European Social Fund Plus

Project description:

The need for ever more powerful and efficient integrated circuits has led to a continuous increase in the integration density of CMOS components over the past decades. The integration density could be doubled approximately every two years (Moore's law). Since the year 2000, this development has been increasingly reaching physical limits. The two-year doubling of performance could then only be achieved through more intelligent computing architecture such as multiple cores, specialized processors and the construction of 3D structures. From today's point of view, electronics can be further developed by magnonics. Transistors that no longer transmit information via electrons but via spin waves or their quanta, the magnons, only generate around 10% of the heat loss of electronic transistors, since hardly any energy is required to change the spin states of the magnons. They can also be used in the terahertz range. As a waveguide material for spin waves, yttrium-iron-garnet (YIG) has proven itself over the past decades as an electrically insulating material with excellent magnetic damping properties in scientific work on magnonics.

INNOVENT e.V. is involved in the world's leading research projects for magnonic components in the field of YIG layers of very high quality produced by crystal growth. In the "Physical Technologies" department, we also deal with methods of physical vapor deposition for the production of thin layers. Together with the "Magnetic and Optical Systems" research department, we are currently working on producing layers using dc sputtering technology in addition to the YIG layers produced by crystal growth. This has the great advantage of being able to transfer layer deposition to established substrate materials such as silicon and to larger substrate sizes in the future.

At the end of 2022, INNOVENT e.V. received a funding commitment within the framework of the guidelines of the Free State of Thuringia for the promotion of securing and recruiting highly qualified personnel for research and development and innovations (Guideline FTI-Thuringia PEOPLE) - funding of research groups. The now approved project "PlasMagnon - scalable plasma-based processes for the production of flat yttrium iron garnet (YIG) thin layers as a base material for magnonic data processing components" took place on January 1st, 2023. With the approval of the project, INNOVENT e.V. will be able to continue working on the development of the technical requirements for the provision of YIG layers by means of gas phase deposition over the next three years.

Project No.: 2022 IVN 0042

Project topic: Preparation of an R&D cooperation project to develop a sensor array based on a generic software interface (GenICam)

INNOVENT intends to commission the above-mentioned elaboration in order to be able to use it to advance the development of a sensor array based on a generic software interface (GenICam).

The funding instrument "Central Innovation Program for SMEs" is to be used for the cooperation project, with which the Federal Ministry of Economics and Climate Protection promotes research in and for SMEs.

Client: INNOVENT e.V.

Contractor: Jade Consult

Type of procedure: according to ThürVgG and ThürVVöA in conjunction with § 12 UVgO by negotiated award without competitive tender

Type of service: service

Scope of the service: €45,000

Period of performance: 07/01/2022 - 01/31/2023

Project No.: 2022 IVN 0029

Topic of the project: Preparation of an R&D project for the research and development of conductive electrospun fiber systems

INNOVENT intends to commission the above measure in order to use it to advance the scientific/technological further development of electrospinning in the field of conductive electrospun fiber systems in the form of an R&D project with the participation of institutional institutions and companies from Germany.

The funding instrument "KMU-innovativ: Materialforschung (ProMat_KMU)" is to be used for the cooperation project, with which the Federal Ministry of Education and Research is promoting cutting-edge research in and for SMEs.

Client: INNOVENT e.V.

Contractor: Jade Consult

Type of procedure: according to ThürVgG and ThürVVöA in conjunction with § 12 UVgO by negotiated award without competitive tender

Type of service: service

Scope of the service: €45,000

Period of performance: 07/01/2022 - 01/31/2023

Project No.: 2021 WID 0018

Project topic:Digitization of business and development processes for interconnected working with additional consideration of mobile working - INNOVENT Digital2030

Goal of the project is the digitalization of all business processes and the interconnected work of the business-oriented research institution INNOVENT. Considering the impact of the Corona pandemic. Basically, this includes the digital data acquisition of scientific activity, analytics and commercial processes.

Project No.: 2021 IVN 0038

Project topic: Preparation of an R&D project for the research and development of self-healing glass surfaces to reduce corrosive effects.

INNOVENT intends to commission the above mentioned measure in order to initiate a European research project. The goal of this research project is to conduct fundamental investigations into the mechanisms of structure-changing processes on glass surfaces, which cause the healing of mechanical and chemical damage to the surface as a result of glass corrosion. The high economic potential of such "self-healing" can only be made accessible once the fundamental processes have been theoretically and experimentally analyzed and understood, and a technologically feasible solution can be derived from them. This complex of model simulations, experimental verifications and sophisticated analyses can only be successfully tackled by a joint project of proven international research groups and institutions with the necessary expertise, which is being prepared with the help of the present project. This includes analyses, the development of the task definition and the search for partners.

The European funding instrument "EIC Pathfinder" is to be used for the cooperation project.

Project No.: AP-6122-BR-2021

Project topic:Intensive consulting and process support by management consultants

In accordance with the consulting guidelines of the Free State of Thuringia, the company receives funding to increase its performance and competitiveness through consulting by independent management consultants - intensive consulting and process support. The results and recommendations for action are recorded in a consultant's report. The funding is provided by the European Social Fund and by the Free State of Thuringia.

Project No.: 2021 WIN 0005

Project topic: Installation of a biological laboratory of safety and protection level S2 with modern equipment for the testing of antiviral, antibacterial and antifungal materials.

The research institution INNOVENT is working on antimicrobial surfaces and materials for various projects. Until now, external service providers had to be involved in order to test the effectiveness of the developments. In the past, this sometimes caused delays. The new laboratory is intended to avoid such delays.

The project belongs to the specialization field "Healthy Living and Health Economy" of RIS3 Thuringia.

Project No.: 2020 IVN 0105

Project topic: Preparation of an R&D project for the development of novel systems for air disinfection by means of singlet oxygen as well as methods for the industrial production of these systems.

The research institution INNOVENT is working on solutions for air disinfection using singlet oxygen. In the medium term, an entrepreneurial value chain for the production of corresponding system solutions is to be created. The necessary developments are to take place in an R&D cooperation project. This project is being prepared with the help of the present project. This includes analyses, the development of the task definition and the search for partners.

For the cooperation project, the funding instrument "KMU-innovativ" will be used. With this instrument, the Federal Ministry of Education and Research promotes top-level research in and for SMEs.

The Gesellschaft zur Förderung von Medizin-, Bio- und Umwelttechnologien e.V. (Society for the Promotion of Medical, Bio and Environmental Technologies) has been commissioned to carry out the work.

Project topic: Consulting by an independent management consultant in the areas of personnel management and organizational development

Beneficiary: INNOVENT e.V.

Project:

In accordance with the consulting guideline of the Free State of Thuringia, the company receives funding to increase its performance and competitiveness through consulting by independent management consultants - intensive consulting and process support. The results and recommendations for action are recorded in a consultant's report. The funding is provided by the European Social Fund and by the Free State of Thuringia.

Project No.: 2020 IVN 0063

Project topic: Preparation of an R&D cooperation project for the development of a motor-adjustable Halbach array for the generation of controllable 3D magnetic field components

The project serves the preparation of an anticipated research project and includes research, market analysis, R&D conception and measures for the acquisition of suitable cooperation partners.

Since 20 years the department Magnetic and Optical Systems of INNOVENT e.V. develops systems for the generation and measurement of magnetic stray fields for industrial and scientific applications. In the case of the here presented project, a funding project shall be prepared. Within this project, a field generating system shall be developed. The focus for future applications will be on the implementation of complex magnetic measurement tasks for industrial applications, and the realization of magnetic field generating prototypes, which can be used for scientific experiments and sensor characterization.

Technically, the realization of the perspective research project is to be implemented by means of Halbach arrays. These magnet arrays consist of several permanent magnets twisted to each other. Compared to conventional magnet arrays, much higher magnetic field gradients or homogeneous magnetic fields with higher field strengths can be generated.

This gives Halbach arrays technical advantages over conventional electromagnets or permanent magnet arrays:

- Higher field strengths compared to conventional magnet arrays due to targeted field concentration,

- Significantly lower space requirements (required installation space for magnetic field volume to be generated) due to higher efficiency,

- Significantly lower weight compared to coil systems with iron core,

- Low energy consumption during use compared to a current-driven electromagnet,

- Maximum field strengths in the magnetic field volume (usable range) and low stray field formation (self-shielding) outside of the magnet system (increase in usability, high compatibility, lower interference field propagation),

- Under an ideal Halbach arrangement, it is possible to maintain high field strength levels when using permanent magnets with a lower energy product compared to classical configurations using magnets with a high energy product.

Project topic: Consulting by an independent management consultant in the areas of personnel management and organizational development

Beneficiary: INNOVENT e.V.

Project:

Development of an organizational development and growth concept to improve competitiveness

Project No.: 2020 IVN 0058

Project topic: Preparation of an R&D project on novel materials and strategies to combat bacterial resistance and biofilm formation regarding bacterial communication (Quorum sensing)

For about 20 years INNOVENT e. V. has been working in the field of antimicrobial agents. In numerous studies and projects on antibacterial efficacy, fundamental scientific findings have been obtained, some of which have been transferred to application in cooperation with companies. A number of results on a laboratory scale are already available, which can be used commercially after further R&D work. These include the synthesis and modification of antibacterial materials, antibacterial coatings for implants, control release systems and antibacterial wound dressings.

The worldwide increase in bacterial resistance makes it necessary to develop new strategies to combat the germs. One possibility is to inhibit the production of biofilms and the bacterial communication system Quorum sensing (QS). Antimicrobial substances are virtually ineffective against infections caused by bacteria that produce biofilms. These bacteria are no longer or only with great difficulty accessible for antibiotics in the formed biofilms. For example, Pseudomonas aeruginosa, a pathogen causing pneumonia and other infections, protects itself from antibiotics by producing biofilms. This formation can be prevented by interrupting the bacterial communication system Quorum sensing (QS).

Some medically relevant biofilms are:

- Cystic fibrosis: The chronic lung infection that severely affects cystic fibrosis patients is caused by the gram-negative rod-shaped bacterium Pseudomonas aeruginosa. Once a biofilm has formed on the lungs, the bacteria cannot be destroyed even by the most aggressive antibiotic treatments. Patients with this hereditary disease form viscous mucus in the lungs due to a disturbed salt transport in the epithelial cells, which forms a good breeding ground for pathogens.

- Contact lenses: Film-forming bacteria can also settle on contact lenses. The germ Pseudomonas aeruginosa in particular plays an important role here. Although it does not occur in the normal flora of the eye, it can get into the eye through mascara sponges or contaminated cleaning solutions for contact lenses. However, corneal inflammation only occurs when there are minor injuries.

- Implants: Bacterial biofilms are responsible for about 60 percent of all infections in implantation surgery. Patient mortality is particularly high when endogenous implants such as artificial joints or heart valves are affected.

- Catheters: Intravenous accesses, such as those required for blood transfusions or artificial nutrition, can also lead to serious infections. Germs of the normal skin flora such as Staphylococcus species or pathogens such as various Pseudomonas species can accumulate on the outside of the access before it is introduced into the patient's blood vessels. There, the bacteria then form a film that, if detached, can cause chronic infections.

- Plaque: The plaque on teeth is not only unattractive, but under certain circumstances also dangerous: caries, gingivitis (bleeding gums) and periodontitis (gum inflammation) can be the result. In addition, germs of the oral flora can enter the blood system through small wounds, which are suspected to cause heart attacks, premature births or diabetes. The great importance of preventing and combating biofilm formation is already apparent from these few examples.

In the previous work at INNOVENT e. V., "individual" strains of bacteria were specifically combated which had a particular effect on the bacterial cell itself, such as the destruction of the cell wall/membrane, introduction of an antibiotic into the cell or through surface effects.

A new challenge is the control or prevention of bacterial biofilms. Bacteria are not lonely, weak unicellular organisms. They are organized, communicative and structured. The vast majority of microorganisms live in complex associations, so-called biofilms. In these structures, which are difficult to destroy, the bacteria show an altered metabolism and a resistance behavior that is many times superior to that of single individuals. Biofilms are responsible for some of the most persistent and dangerous infections as listed above.

The Polyclinic for Conservative Dentistry and Periodontology of the University of Jena was commissioned to carry out the work.

Project No.: 2020 IVN 0053

Project topic: Preparation of an R&D project to develop processes for the surface functionalization of wood-based materials in a regional value creation network

For about five years INNOVENT has been working on the functionalization of wood and WPC surfaces. Such investigations were first initiated at INNOVENT in 2015 with the start of the international research project PlaCoW (Plasma coatings for wood and wood-polymer-composites). After fundamental investigations of the influence of atmospheric pressure plasma technology and flame treatment technology on the base material wood, technical modifications of such coating technologies were carried out. By means of these modifications, the introduction of chemical precursors can be achieved, which in turn enables the deposition of thin functional layers on surfaces. The work carried out within the framework of the R&D project, which has already been completed, has made it possible to gain fundamental scientific knowledge and to demonstrate the possibility of creating coating properties such as antibacterial, fungicidal, water-repellent and/or paint adhesion-improving.

Results are already available on a laboratory scale, which can be used economically in the future after further R&D work. Several conditions must be met for this to happen, and these are to be addressed in a project funded by the "RUBIN - Regional Entrepreneurial Alliances for Innovation" funding instrument. Core topics are the upscaling of coating technology (reproducibility, economic efficiency, ecology) as well as the further processing of coated materials by different technologies to innovative, competitive products.

The economic and innovation consultancy Prof. Dr. Franz Rudolph was commissioned to carry out the work.

Investment in research-related equipment infrastructure

Project No.: 2019 WIN 0003

Project topic: Development of a measuring station for process control and layer analysis of chemical, electrochemical and plasma chemical surface functionalization of different substrate materials

In the context of increasing demands on components and their surfaces, surface technology is becoming increasingly important. For this purpose, the business-oriented research institute INNOVENT e. V. has been successfully developing new coating systems and innovative surface functionalization for over 25 years. Particularly in the Department "Surface Technology", modern coating processes are applied. Examples of these processes are the generation of thin films, by using atmospheric pressure plasma, flame pyrolysis or the process of plasma chemical oxidation. The associated technological developments include a wide variety of chemical, electrochemical and plasma-chemical surface treatments of numerous materials. At INNOVENT, it is possible to treat the following materials: light metals (aluminum, magnesium, titanium and the corresponding alloys), stainless steels and special materials (Dispal®, molybdenum, tungsten), as well as glass and ceramic materials, wood, textile fabrics and fibers.

Within the scope of the planned investment, a new measuring station is now being built which combines sample preparation as well as process monitoring and layer analysis. This is done in order to successfully meet future challenges in the development of new specific layer systems. Such measures ensure the future competitiveness of the institute. The project includes a glovebox for safe working with sensitive surfaces and porous materials, whose cavities must be filled with a defined gas for analytical purposes. Furthermore, a gravimetric titrator is applied. This delivers fast and precise measurement results in wet chemical analyses for process monitoring. A glow discharge spectrometer for detecting the achieved layer properties and functionalities is also included.

Because INNOVENT operates as a non-profit research institution, industrial customers, and small and medium-sized enterprises also have access to our unique know-how and modern instrumentation and analytical equipment. Due to this, such organizations can also benefit from the location Thuringia.

Project No.: 2019 IVN 0118

Project topic: Preparation of an R&D project to investigate the distribution and mobility of alkali ions in glass coatings and glass surfaces

The project serves as the research and preliminary investigation for the analytical possibilities and necessities of the time- and location-resolved recording of migration movements. Specifically, network changing chemical components in glass are recorded. This is necessary for the research and development, in order to refine glass surfaces through the application of coatings and modifications.

Molecular dynamic modelling (MD) is an excellent tool for obtaining microscopically based information on alkali ion dynamics. With simulations of the corrosion process, as well as the behavior of possible protective coatings, predictions can be made with high accuracy, in respect to different configurations and environmental conditions. As a result, time-consuming and costly investigations, for each new configuration can be avoided. The simulations require experimental verification and must be adjusted with the results. The R&D project aims to investigate different economically relevant glass configurations. The focus is in the interaction of simulation and experiment, and to optimize the surface technology. Examples of these glass configurations include: float glass in the architectural sector, container and service glass and special technical glass.

The Fraunhofer Institute for Microstructure of Materials and Systems IMWS was commissioned to carry out the work.

Project No.: 2019 IVN 0117

Project topic: Preparation of an R&D project to develop processes for the production, processing, and use of functionalized basalt fibers, in a value-added network

The applicant, in cooperation with four other companies, is developing solutions for the in-situ functionalization of basalt fibers. This is within the framework of the BMBF's "Growth Core Potential" funding instrument. The project will end on 31.12.2019. Laboratory-scale results are already available and can be used commercially, after further R&D work is achieved.

For this, several conditions have to be fulfilled, which will be worked on in a project supported by RUBIN. Core topics include: the upscaling of basalt fiber production and functionalization (reproducibility, economic efficiency, ecology), as well as the further processing of basalt fibers using various technologies. This allows for the production of innovative and competitive products.

The economic and innovation consultancy Prof. Dr. Franz Rudolph was commissioned to carry out the work.

Project No.: 2019 FE 9071

Project topic: Cementless, antibacterially functionalized ceramic femoral condyles with metal-free instruments (KeraKon)

Sub-theme: Antibiotic-containing coating for protection against periprosthetic infections

The so-called aseptic loosening, as well as periprosthetic infections, are the most feared complications when replacing knee or hip joints with endoprostheses in implantology.

With this in mind, the joint project plans to develop and test an oxide-ceramic, antibacterial knee prosthesis. A further goal is to provide the corresponding metal-free medical instruments for implanting the prosthesis.

The tasks of the subproject of INNOVENT include the provision of antibacterial coatings. These coatings will have a long-lasting antibacterial effect to protect against periprosthetic infections, and positively influence the ingrowth of the prosthesis in the surrounding tissue (osseointegration). A further subject of the work is to establish a coating technology for medical devices relevant for endoprostheses.

Project No.: 2018 IVN 0098

Project topic: Preparation of an R&D project to develop innovative glazing and glazing systems for cultural assets

Glass is a multifunctional, transparent material with a unique combination of properties. In combination with INNOVENT's expertise, problems involving use (i.e. changed conditions due to new requirements), and the protection of cultural assets, can be effectively addressed in the field of glass.

For this reason, requirements for the protection of cultural assets are to be combined with new technological possibilities for the functionalization of glass and glazing technology. This will be achieved throught a cooperative R&D project, planned for the near future.

The BIT GmbH was commissioned for the implementation of the work.

Project No.: 2018 IVN 0094

Project topic: Preparation of an R&D cooperation project for the development of a fiber coating process to increase the service life of fiber ropes

Ropes consisting of high-strength polymer fibers, known as HM-HT fibers (high modulus - high tenacity), have a similar or even higher tensile strength, compared to steel wire ropes. Also, the fibers have a three to five times lower average load-bearing weight. This results in up to seven times greater breaking lengths than steel wire ropes. The so-called fiber-fiber friction inside the rope is considered the main focus of development. This is one of the main damage mechanisms in dynamic applications of fiber ropes.

The texulting GmbH was commissioned to carry out the work.

Investment in research-related equipment infrastructure

Project No.: 2018 WIN 0011

Project topic: Expansion of the technical facilities for chemical, electrochemical and plasmachemical processes… Surface functionalization of various substrate materials include, primarily aluminum, titanium and magnesium alloys, as well as glass and ceramics

Brief description of the project:

In recent years, the "Electrochemistry" working group of the business-oriented research institution INNOVENT e. V. Jena, has been working on numerous development projects. These include the development of technologies for the chemical, electrochemical and plasma-chemical surface treatment of various materials. Examples of these materials include: light metals (aluminium, magnesium, titanium and their alloys), stainless steels and special materials (Dispal®, molybdenum and tungsten), as well as glass and ceramic materials. The results of these projects have been transferred to the industry, for utilization on a significant scale. The technology transfer is the reason to continue along this successful path, and to pursue and expand the possibilities of this surface functionalization. The investment in modern plant technology will also make an innovative contribution. Such input, will support the competitiveness of the optical and medical technology industries in the state of Thuringia.

Objectives of the project:

New premises are being created for the new technological advancements of plants such as i.e. the process of plasma-chemical oxidation. This will open up new fields of application for these materials with the surface treatment of light metals. It will also offer and expand a useful supplement to the surface treatment processes already in industrial use. The already existing competence in the field of chemical and electrochemical surface treatment will be expanded in such a way, that a new specialist competence for surface treatment will be created. Such a competence, particularly in reference to light metals and other materials, has previously not been available in Thuringia.

Project topic: Preparation of an R&D project for the development of an innovative hot melt adhesive, for use in the textile industry and textile restoration

The application for an R&D project will be prepared, within the framework of the project.

INNOVENT holds a patent for the production of transparent melting starch fatty acid esters, which can be used as melts and therefore solvent-free as adhesives. After initial research, potential was identified in the fields of "technical textiles", "clothing textiles" and possibly as a by-product for textile restoration. To obtain a market-relevant product, some specific developments are still required.

The Textile Research Institute Thuringia-Vogtland has been commissioned to carry out this work.

Innovation voucher A: preparation of R&D cooperation projects

Project No.: 2017 IVN 0067

Project topic: Preparation of an R&D project for the development of innovative conservation: These concepts will be applied for existing buildings worthy of protection. They are a contribution to sustainable, regional, structural change in Eastern Thuringia.

One of the future tasks of structurally weak regions such as east Thuringia, is to effectively confront the challenges of demographic change. The combination of technological and social innovations, cross-industry protection of cultural assets, and the growing tourism industry in Thuringia, hold considerable potential. These factors can help the region to achieve new radiance and economic power. Targeted research activities are intended to promote the ability of the players (industry, crafts, culture, tourism industry), in the above-mentioned topics, to bring about sustainable structural change through innovation and networking. The aim of the measure, is INNOVENT’s successful participation in a funded program called "WIR! - Wandel durch Innovation in der Region" (Transformation through innovation in the region). This request to send in projects was published by the Federal Ministry of Education and Research.

Thielbeer Consulting was commissioned to carry out this work.

Project topic: Preparation of a cooperative R&D project for the development of basalt-filled plasters with antibacterial and antifouling properties

Within the framework of the project, the application for an R&D project should be prepared.

The antibacterial and anti-fouling properties of certain basalts are to be used, to create a corresponding functionalization of plasters for different applications. The technical, chemical-biological and organizational issues relevant to achieving market maturity, are to be comprehensively answered in one (or more) collaborative research projects.

EBF Dresden GmbH has been commissioned to carry out this work.

Innovation voucher A: preparation of R&D cooperation projects

Project No.: 2016 IVN 0033

Project topic: Preparation of an R&D project for the demand-oriented development and production of continuously spun basalt fibers with the aim of achieving a consistent and application-oriented quality of fiber materials along the value-added processes.

Within the framework of the project, the application for an R&D project should be prepared. The project is based on basic research at INNOVENT. The research was about the effect of different mineral mixtures on the properties of basalt fibers. In addition to research and market analyses, the project includes the investigation of the problems, the implementation of economic efficiency calculations and the development of an R&D concept.

The Forum Technologie & Wirtschaft e.V. was commissioned to carry out the work.

Innovation voucher A: preparation of R&D cooperation projects

Project No.: 2016 IVN 0012

Project topic: Preparatory activities for the application within the framework of an R&D program at the Federal Government for research of innovative surface treatments with active substances found in the nature, for the permanent functionalization of surfaces

Within the framework of the project, the application for an innovation forum is to be prepared. The common basis for the research cooperation will be the use of innovative surface technology and processes for application-oriented integration, for the use of natural active ingredients. The entire necessary value-added chain will be examined. This reaches from the cultivation and raw material extraction to the application of products, as well as the application of different functionalities. All this will be examined from the perspective of potential areas of application.

Forum Technologie & Wirtschaft e.V. has been commissioned to carry out the work.

Business-related infrastructure

Research and development projects of business-related research institutions

Project No.: 2016 WFN 0021

Project topic: In situ XPS investigations, on the diffusion of alkali and alkaline earth ions in near-surface regions, and SiOx layers on heated glasses

The project aims to develop and validate a meaningful analysis methodology for the development of effective and cost-effective protective coatings. These protective coatings enable a simpler and more cost-effective production of refinement layers on glass surfaces. In addition, these coatings can serve as a prerequisite for the development and application of refinement layers, as well as for increasing their long-term stability.

An important aspect is the temperability of the protective coatings, which is becoming increasingly important for many applications. Examples are the temperable coating systems on flat and container glass. Another aspect that should be noted is the improvement of energy efficiency. A better knowledge of the effectiveness of the barrier layers and the diffusion processes can help to optimize the coating and tempering processes in glass finishing. This could potentially help glass manufacturers in Thuringia to develop innovative products and processes.

The Fraunhofer Institute for Silicate Research ISC and the company Eurofins Umwelt Ost GmbH were commissioned to carry out this work.