Case of Damage Investigations

We have many years of experience in the field of damage analysis. Additionally, we provide efficient technical equipment, which is capable of tracing damage to coatings and composite systems, back to probable causes.

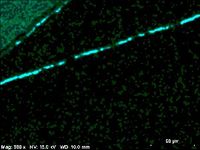

Small defects in coatings can often be easily examined using a microscope. By supplementing microscopic methods with element or molecular analyses, the cause of damage can be further determined. For example, the delamination of a powder coating due to unsuitable or improper phosphating, can be described in detail by combining SEM images and EDX spectrums. Unintentional delamination is often caused by inadequate cleaning or pretreatment, or other deviations from "normally functioning" processes. Depending on the problem, surface contaminations are detected by analytical methods such as FT-IR, HPLC or GC/MS.

In other cases of damage, it may be useful to adjust the ambient and application conditions, e.g. to determine the effects of wet and damp storage on test bondings, and to assess their influence.

The evaluation of the damage cases is carried out under consideration of the materials used. The selected process parameters and the application and exposure of the parts are also taken into account. As a rule, in order to be optimally informed about materials and processes, it is advantageous to undertake a damage investigation.

If necessary, we endeavor to find ways of avoiding future damage and to make processes more robust.

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48