Welcome to the Research Area "Surface Technology"

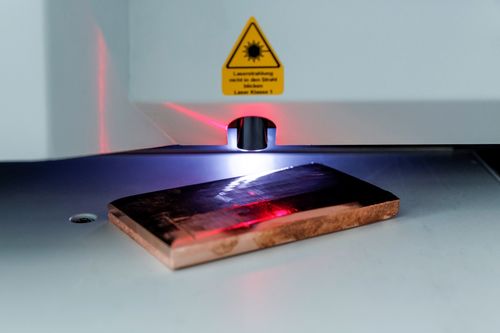

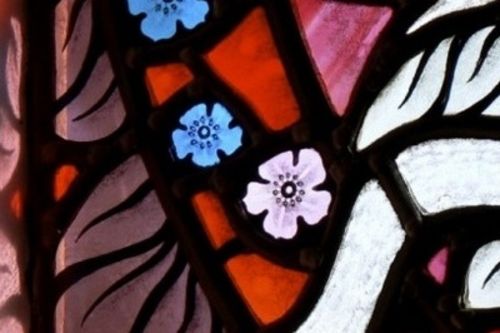

We are engaged in process and equipment development for the modification, coating or sterilization of various materials such as metal, glass, textiles, ceramics or plastics under normal conditions. Special attention is paid to process development of combustion CVD, remote combustion CVD and plasma CVD technologies. The classical low-pressure coating processes are also maintained and further developed.

We are Your Partner for Innovation and Research in:

- Liability improvement

- Improvement of the corrosion protection

- Surface functionalization (hydrophilicity, hydrophobia, oleophobia)

- Functional optical layers (transmission enhancement or antireflection, switchable layers, photocatalysis)

- Wear and scratch protection layers

- Barrier layers

- Friction reducing coatings

- Adhesive Bonds

The realization of your projects is achievable with the help of our high-performance workshop with a design office, up to the prototype stage.

Skills & Expertise

Dr. Sebastian Spange

Head of Department

Surface Technology

e-mail

phone: +49 3641 282551