Flame Pyrolysis from Roll to Roll

Functional coatings of roll and web materials

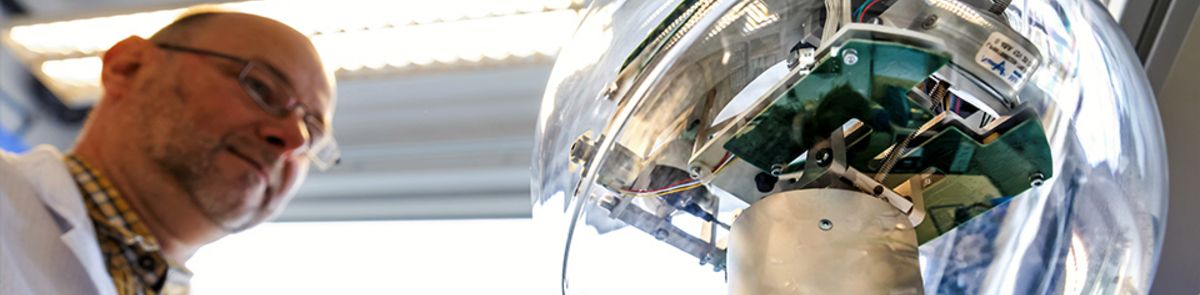

The project is aimed at companies that would like to functionalize materials as rolled goods (web materials), using CCVD technology (Combustion Chemical Vapor Deposition). The integration of the CCVD technology established by INNOVENT, also known as flame pyrolysis, in roll-to-roll (R2R) systems enables the functionalization of web materials under atmospheric pressure conditions. By adding suitable chemical precursors, thin functional coatings, such as the Pyrosil® (SiOx), developed by INNOVENT, can be realized quickly and cost-effectively in a combustion process.

Within the scope of this user project, INNOVENT supports interested companies with the available expertise including system and equipment engineering.

Project content:

Practical relevant test series for the surface treatment of web and roll goods are applied, such as: polymer or metal foils, textile materials or paper, using flame pyrolytic SiOx deposition at a R2R system.

Key aspects:

- Is the selected material in principle suitable for flame pyrolytic treatment under the present conditions?

- Is a relevant surface effect achieved (adhesion, barrier, functionalization, haptics)?

- Which parameter combinations (speed, precursor concentration, burner capacity, cooling etc.), offer the best chances of success?

- How long-term stable and storage compatible are the achieved effects?

- What is the optimal time window for further processing?

- Are the determined treatment parameters and results technically/technologically feasible for an industrial application?

The tests are carried out and documented by INNOVENT using the existing coating equipment and technology. The results are continuously and exclusively available to the participants.

Possible applications:

- Creation of barrier layers (e.g. oxygen barriers with OTR values < 1 cm³/(m²-bar-d) on PET)

- Improving the absorption of wet chemical finishes on textile materials or paper

- Permanent antibacterial properties

- Improvement of the adhesion properties of subsequently applied sol-gel layers on foils

The main areas of application for the process are food packaging or technical textiles.

Project information:

Project start: | Not yet determined - Registration still possible after project start |

Project duration: | 10 months |

Project costs: | 5.500,- € (plus VAT) |

The invoice will be issued at the beginning of the project.