Materials for the manufacture of additives in the medical field are becoming increasingly important. Therefore, the development of materials for additive manufacturing is a research focus of the Biomaterials division. In cooperation with qualified partners, we are successfully implementing these materials to the printing processes.

Calcium phosphates have long been used as implant materials in areas of hard tissue due to their similarity to the mineral phase of human bone and their osteoconductive properties. Currently, these materials are clinically utilized as granulates, hardenable cements or prefabricated molded bodies with simple geometry. However, they are rarely used as a patient-specific implant with individually adapted shape and structure.

Based on this consideration, the development of powder binder systems, which can be processed in a conventional 3D powder printing process to obtain stable three-dimensional molded bodies with a given geometry, is a focus of our research. As powder components, we use pure calcium phosphates (tri- or tetracalcium phosphate) or formulations with other compounds (calcium carbonate, hydroxyapatite) which harden at defined points with the aid of aqueous binder fluids. Analysis of the resulting crystal phases is carried out using X-ray diffraction.

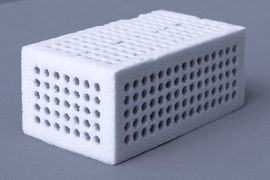

Complex bodies can be printed out with such optimized binder systems. The efficiency of the printing process has already been demonstrated by the fabrication of printed bodies, with crossing channels in the x, y and z axes, and of filigree facial skull structures.

The mechanical stability of porous molded bodies can be substantially increased by infiltration with biocompatible radical cross-linkable monomers. Cyto-biocompatibility of printed and post-treated specimens has been demonstrated by in vitro experiments with selected cell lines and in in vivo studies.

Furthermore, we have developed photo curing material systems for contemporary additive manufacturing processes, such as stereolithography (SLA), digital light processing (DLP) or multi-photon polymerization (MPP). These novel photo curing resins are outstanding in their material properties in a cured state. The material flexibility can easily be varied according to the desired application of the components. So it is well distinguished for use in earmolds, septum buttons or epitheses.

Gabriele Grimm

e-mail

Phone: +49 3641 282555