Adhesive Technology

Bonding is a powerful joining technology that opens up new areas of application, from micro to macro, and from living tissue to high-temperature usage. The vast requirements of the adhesive composite, and the manufacturing processes, necessitate an adhesive technology which must always be tailored to the specific application.

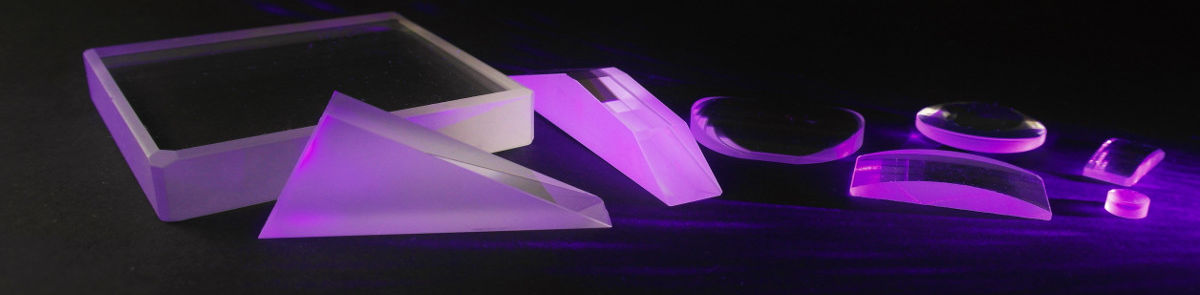

The diversity and performance of adhesive composites, is also reflected in the incidence and variance of the fields of application. This includes: microtechnology, building trade (including lightweight construction), optics and sensor technology, as well as medical technology. There is also great variability in the geometry and type of substrates such as: metals, plastics, ceramics, glass and natural materials.

Because of the many different requirements, viable adhesive solutions require the best possible adaptation for the respective case of use.

The development and modification of adhesives are adapted according to the respective application and requirements of the customer. (Please refer to Standarts, Norms & Specifications.) The characterization and suitability testing of adhesives is carried out by using the in-house equipment.

The selection, modification and formulation of the adhesives (the pretreatment of the parts to be joined), and the process control during production, stem from its requirement profile. This includes the adhesive composite and any existing production-related boundary conditions.

Composite and loading tests, using universal testing machines and/or climatic testing technology, are utilized to characterize casting compounds and composite materials. Furthermore, methods of material characterization such as thermal analysis, or the uncomplicated procedure to determine Shore hardness, are also utilized.

The digital hardness tester 3140 HO4 from Zwick GmbH & Co.KG, is used for hardness testing Shore A and Shore D, on plastics and elastomers. The test is performed in accordance with standards, e.g. DIN ISO 7619.

In Shore hardness testing, the resistance to the penetration by a body, is determined using a test stamp. The shape of the body, as well as the spring force and measurement of time, correspond to the sample to be analyzed, or the method to be used. The hardness value is obtained by pressing the test stamp onto the sample. Various operating modes allow for the setting of different measurement series, measuring ranges and tolerance limits.

Choice of Methods:

- Shore A ⇒ e.g. soft rubber, elastomers, natural rubber

- Shore D ⇒ e.g. plastics, rigid thermoplastics, hard rubber

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48