The demands on adhesives in regard to application temperature range, elasticity, adhesion to certain substrates, thermal or electrical conductivity, application rheology, thermal expansion, curing kinetics and mechanism and a number of other properties can be very diverse. It is often difficult or impossible to find an adhesive, which is optimally suited for a specific purpose among the multitude of commercial adhesives available on the market so that a special formulation must be developed for this purpose. Sometimes this is the only way to optimally fulfill the respective application conditions and requirements.

In this way, adhesives can be imparted a defined electrical or thermal conductivity. An example of our work in this area is the development of a composite material with adapted thermal conductivity as well as the development of material compositions having adjusted coefficients of thermal expansion regarding the components to be bonded by adding appropriate functional additives. In this context, these factors play a decisive role in optical components that are exposed to high and fluctuating temperature loads, along with the adjustment of the refractive indices and low outgassing.

In addition to extreme climatic conditions and temperature fluctuations, further stability and resistance requirements can be placed on composites and thus on the adhesive. In medical applications, chemically resistant adhesives are often required (especially with regard to the use of cleaning and disinfecting substances), which must simultaneously withstand sterilization (e.g. temperature, radiation and hydrolysis load). The flexibility of adhesives can be specifically influenced by the use of fillers or elasticizing substances.

In order to expand our property portfolio, other projects are concerned with the variation of curing possibilities resp. mechanisms of the adhesive reaction, so that e.g. an only heat curing can be combined with an additional pre- or curing via UV-radiation.

Supplementing the optimization of adhesives according to the application parameters, special adhesives can be formulated resp. optimized for the permanent or temporary fixation of components or for distance regulation.

We offer customized adhesive modification or development, adapted to your specific application as well as testing and characterization of the adhesives.

Superglue Resistant to Moisture

and with Improved Thermal Stability

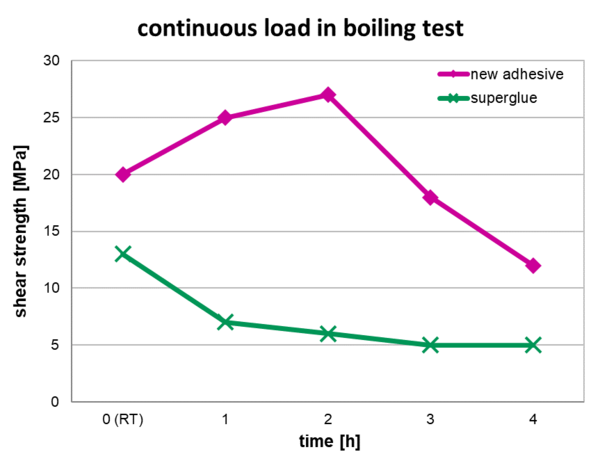

The properties of a cyanoacrylate-based superglue have been significantly improved in terms of its moisture and heat stability. The basic advantages of a one-component adhesive polymerizing at room temperature and an adhesive effect for numerous substrates with high strength are retained.

The property profile of the new adhesive formulation can be summarized as followed:

- significant improvement of the adhesive strength after exposure to heat in the temperature range up to 100 °C under permanent load and a maximum load up to 130 °C

- significant improvement of the adhesive strength after exposure to moisture

- at room temperature under permanent load up to 3 years water storage and at elevated temperatures up to 100°C

Therefore, the adhesive modification enables the use of adhesive composites in technical applications and outdoors.

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48