With the existing climatic test technology, test specimens and components can be exposed to various climatic, even changing loads. Both temperature and humidity can be specifically adjusted and varied. A thermal shock chamber is available for particularly rapid temperature changes. The test chambers are designed and equipped so that e.g. samples, components or assemblies can be supplied with the appropriate media (e.g. electrical, pneumatic, hydraulic, etc.) during climate loading. Other environmental influences such as salt exposure, UV radiation and weathering can be simulated and tested (also according to standards) using appropriate test equipment.

Climatic Test Chambers

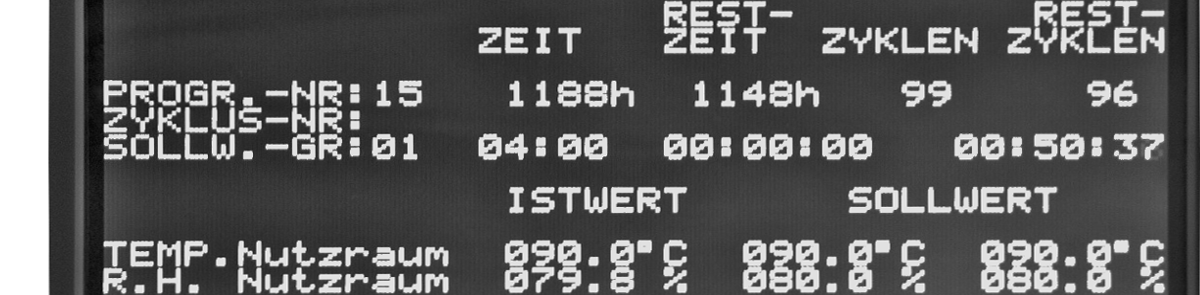

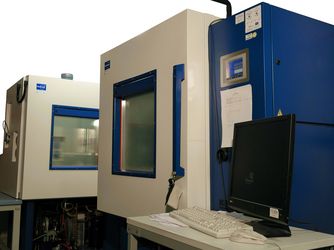

| Manufacturer: | Feutron Klimasimulation GmbH |

| Model: | Klimaprüfkammer KPK 200 |

The climate test chambers can be used, among other things, for testing the resistance of components and test composites, for conditioning materials and specimens or for burn-in procedures for e.g. adhesive composites.

Testing Standards:

- DIN EN 60068-2-1 / -2-2 / -2-14 / -2-30 / -2-38 / -2-78 / -3-1

- MIL StD 883 D Meth. 1010.7, 1011.9

- IPC-TM-650

- DIN EN 50017

Various test chambers are available for climate simulation. The climate test chamber KPK 200 from Feutron GmbH is presented here as an example.

| Technical Data (standard version): | ||

|---|---|---|

| Nominal test chamber volume | 280 dm³ | |

| Test room dimensions | 720 × 690 × 560 mm | |

| Allowable load | 90 kg (distributed over 3 grids à 30 kg) | |

| Feed-through openings | 2 pieces (Ø 75 mm) | |

| Temperature range | -75 °C to 180 °C | |

| Climate range | 10 °C to 95 °C | |

| Rate of change | ||

| Heating | 4 K/min | |

| Cooling (climate operation) | 0.6 K/min | |

| Cooling (temperature operation) | 3 K/min | |

| Humidity range | 10 to 98 % r. H | |

| Additional Equipment: | ||

| Hdditional humidifier heating | for faster humidity control (humidification) | |

| Dry compressed air supply device | for faster humidity control (dehumidification) | |

Temperature Shock Chamber

| Manufacturer: | Feutron Klimasimulation GmbH |

| Model: | TSK 200 |

The temperature shock chamber is a combination of two temperature chambers, which are connected by a movable rack and used alternately.

The test material is subjected to rapid temperature changes by being alternately exposed to low and high temperatures. The degree of test severity depends on the two chamber temperatures, the transfer time and the number of cycles.

Each chamber provides with a viewing window for visual monitoring. For measuring and supply lines such as compressed air, electrical or hydraulic, appropriate feedthroughs and entrances are available in each chamber as well as in the rack.

Testing Standards:

• DIN EN 60068-2-14 Na, Nb

• MIL StD 883 D Meth. 1010.7, 1011.9

• IPC-TM-650

• DIN EN 60068-3-5 (single chamber mode)

| Technical Data: | ||

|---|---|---|

| Cold chamber | -75 °C to +180 °C | |

| Hot chamber | +10 °C to +200 °C | |

| Rack volume | 160 dm³ | |

| Transfer time: | from < 10 sec | |

| Maximum weight of test sample: | 50 kg (distributed over 3 shelves) | |

| Rate of change in single chamber operation | ||

| Hot chamber | heating | up to 8 K/min |

| cooling | up to 1 K/min | |

| Xold chamber | heating | up to 8 K/min |

| cooling | up to 7 K/min | |

Humidity Chamber

(Incubator)

| Manufacturer: | Memmert |

| Model: | HCP 108 |

A homogeneous atmosphere and temperature distribution can be set in the humidity chamber. Thus optimal living conditions for organisms such as fungi or bacteria can be generated. It is used for the cultivation of fungi as well as bacteria and testing of material under exposure to microorganisms, but also for the storage and conditioning of components, test specimens or materials under defined conditions.

| Technical Data | |

|---|---|

| Temperature range: | from RT + 8 °C |

| up to 95 °C with humidity control | |

| up to160 °C without humidity control | |

| Active humidification & dehumidification control: | 20 to 95 % r. H |

| Number of program steps: | 40 ramps from 1 min to 999 h |

| Interior space (max.): | 560 × 480 × 400 mm |

| 108 l | |

| Accessories: | perforated plate / grating |

Autoclave / Steam Sterilizer

| Manufacturer: | CertoClav Sterilizer GmbH |

| Model: | CertoClav Connect |

In addition to sterilizing consumables, the autoclave can also be used to investigate the long-term behavior and service life of materials and thus serves for material testing and quality assurance.

Possible Operating Modes & Application Examples:

• Autoclaving of materials and test samples

• Provides information on material properties regarding:

- Dimensional stability

- Corrosion resistance

- Ageing behavior

- Pressure resistance

- Long-term behavior & service life

- Coating quality

• Test for sterilizability of adhesives, casting compounds, composite materials, etc.

Possible Testing Standards:

• GSB AL 631

• HAST Test

• ICP - TM 650

| Technical Data | |

|---|---|

| Temperature range: | max. 140 °C |

| Interior space (maximum): | approx. H: 28 cm & Ø: 25 cm |

| 18 l | |

| Material of the chamber: | stainless steel |

| Accessories: | wire basket, T- & ρ-sensor |

| Feature: | freely programmable |

| electronically controllable | |

| long-term cycles possible (up to 1 week) | |

High-Performance Safety drying Oven

| Manufacturer: | Binder GmbH |

| Model: | MDL-115 with coil coating extension |

This high-performance drying oven operates in the temperature range up to 350 °C with an air throughput of up to 400 l/min. Due to the integrated coil coating drawer, it is ideally suited for the simulation of hot air short cycle or coil coating applications. The heating capacity is 9 kW for a furnace volume of approx. 115 liters. The MCS controller can store 25 programs with 100 sections each for a maximum of 500 program segments.

With the coil-coating drawer, the oven is particularly suitable for very rapid heating of test specimens and short heating cycles. Due to the programmable control and the high heating power, even demanding temperature control and cooling programs (based on the ambient temperature) can be carried out, e.g. curing or drying processes with defined temperature control.

Salt Spray Chamber / Corrosion Test Chamber

| Manufacturer: | Köhler Automobiltechnik GmbH |

| Model: | HKT1000 WKT |

In industrial practice, the salt spray test (SST) is a frequently used test method for proving the product quality of semi-finished products with regard to their corrosion resistance. The more stringent test conditions compared to the "natural" process have the advantage of shortening the test time, but also the disadvantage of the possibly affected corrosion mechanism.

Standard-compliant salt spray tests are carried out.

Possible Operating Modes for accelerated Corrosion Tests:

• salt spray test

• condensation test

• constant and alternating climate test

• condensation water test

Application Examples:

• Testing of coatings on metal substrates (with and without scratch) to determine the maximum loading time

• Comparative investigations on the quality of coatings by means of intermediate tests with increasing loading time

• Evaluation of delamination, bubble formation, corrosion starting from the scratch

• Evaluation white rust for zinc, filiform corrosion for aluminum

Possible Testing Standards:

DIN EN ISO 4611

DIN EN ISO 6270-1 / -2

DIN EN ISO 9227

DIN EN ISO 11997-1 / -2

ASTM B 117

DIN EN 60068-2-11

ASTM G-85

Device Configuration:

• Operating settings:

– Test chamber volume: 1000 l

– Climate area: RT +5 °C to 60 °C

• Stable conditions due to dosing pump

• Freely programmable test conditions

Solar Radiation Simulation and Weathering Testing

| Manufacturer: | Atlas GmbH |

| Model: | Beta + |

The test device simulates natural weathering and provides reliable information on the weather resistance of all materials within a short time.

It is suitable for testing light and weather resistance of many materials and coatings.

Due to the double irradiance – 2 suns: up to 120 W/m² – compared to normal sun exposure on earth, UV weathering tests can be reduced to half the usual time.

Device Configuration:

• 3 air-cooled xenon lamps (à 2200 W)

• 4000 cm² sample area

• Tests with high irradiance up to 120 W/m2 (2 times the irradiance of the sun)

• Input and control of:

- Irradiance (300 - 400 nm)

- Black standard temperature

- sample chamber temperature

- relative humidity

• Ageing-stable XENOCHROME filters to simulate daylight outdoors and/or behind window glass

• XENOSENSIVE on the sample carousel 300 - 400 nm for measurement and control of irradiance (in W/m2) and BST (°C) at sample level

• Selectable temperature control either by sample chamber temperature (max. 70 °C) or double control: sample chamber temperature and black standard temperature (up to 130 °C)

• Ventilator -controlled temperature difference between sample chamber and black standard temperature• Ultrasonic humidification system for humidity control

Possible Test Standards according to Manufacturer:

• AATCC TM 16 TM 169

• ASTM G151 G155 D6695

• DIN EN 513

• GME 60292

• GMW 3414TM

• ISO 105-B02 105-B04 105-B06 11341 3917 4892-2 12040

• JASO M 346

• MIL STD 810 G

• RAL GZ 716/1

• VDA 621-429 621-430 75202

• VW PV 1303 PV 1306 PV 3929 PV 3930

⇒ Please do not hesitate to contact us for questions and further information about our R&D and services offered. |

Overview of our Technical Equipment

- 3D Microscope

- Atomic Force Microscopy

- Buchholz Hardness Test

- Coater

- Coating Thickness Measurement

- Colorimeter & Spectrophotometer

- Cross Cutting Test

- Drop Ball Impact Test

- Environmental Test Engineering

- FT-IR (ATR) Spectroscopy

- Gloss Level Analysis

- Grind Gages (Grindometer)

- Irradiation Technology

- Measurement of Corrosion Current

- Mechanochemical Surface Treatment

- Mandrel Bending Test

- Palamat

- Panel Press

- Plastics Technology

- Pneumatic Hot-Melt Dispenser

- Potentiostat / Galvanostat

- Powder Coating

- Raman Spectroscopy

- Sample Preparation Technique

- Scratch & Scribing Tools

- Stirring & Mixing Technique

- TERA Ohmmeter

- Thermal Analysis

- Ultrasonic Testing System

- Universal Testing Machines

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48