Sample Preparation Technique

In addition to the facilities ans possibilities provided by our in-house workshop, the department also has further equipment for defined sample preparation, which work under wet conditions as well as in dry ones. These include a parallel grinding machine of the company Netzsch, an abrasive wet cutting machine (Conrad Apparatebau) and a band saw (Proxxon), where components and samples of different materials can be prepared for analyses.

For very small samples and surfaces, which are difficult to reach, a Micromot multi-functional grinding machine (Proxxon) with a flexible shaft and various grinding as well as cutting tools is suitable. This device can be operated either hand-held or in a tool stand.

Test Specimens

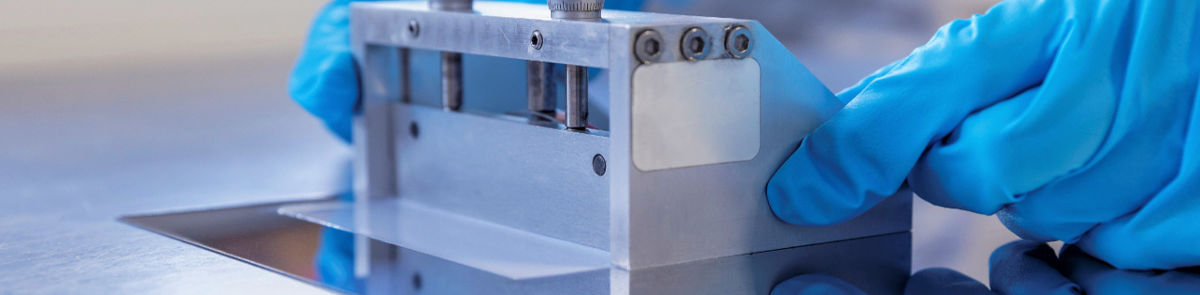

Manufacturing appropriate test specimens of adhesives, casting compounds, composite materials or coatings (varnishes) is the basic requirement for all subsequent investigations. However, it is not unusual for the preparation of specimens in high quality causing greater effort than actual testing.

Different manufacturing processes and devices are applied in the production of the test specimens.

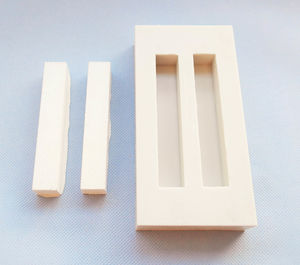

- Initial forms ⇒ a formless material is transformed into a solid shaped object, e.g. casting in an appropriate mold (for adhesives, casting compounds, polymers etc.)

Application Examples:

► Adhesive is brought into a cuboid shape (bending test)

► Extrusion of a foil out of granulate - Forming ⇒ a solid object is reformed without change of mass e.g.pressing (usually polymers)

Application Examples:

► Foils pressed to a solid object

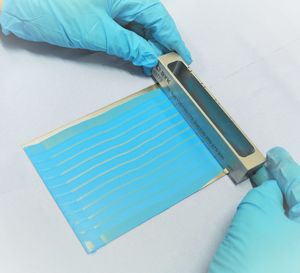

► Fabrics / nonwovens pressed to a molded object - Cutting ⇒ solid objects are fbrought into desired shape by material removal (sawing, drilling, milling, grinding, turning etc.)

Application Examples:

► Shoulder bars are manufactured out of a plate (tensile test)

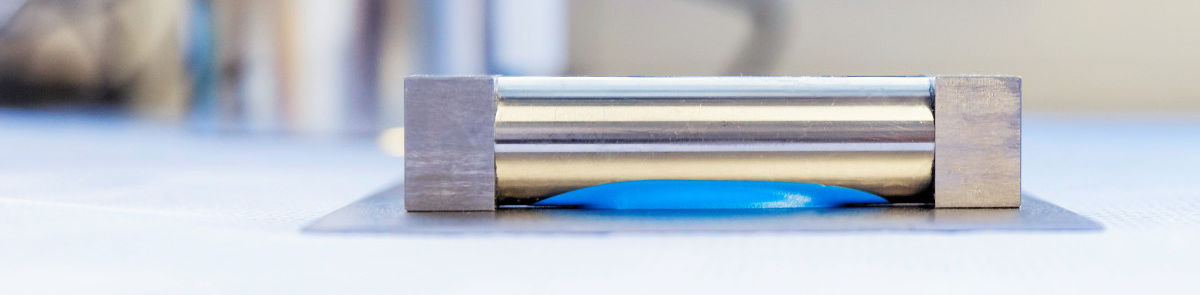

► Plane-parallel cylinders or cuboids for expansion tests - Joining ⇒ long-term connecting of serveral components e.g. by adhesive bonding

Application Examples:

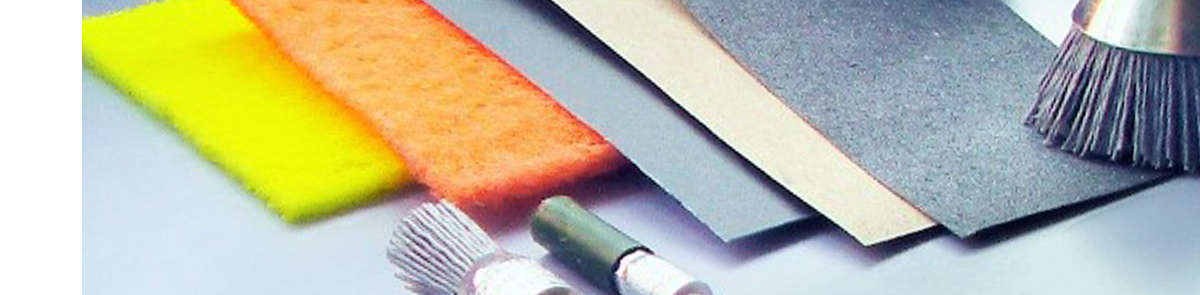

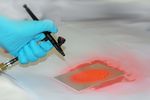

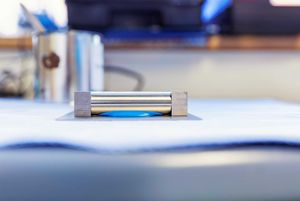

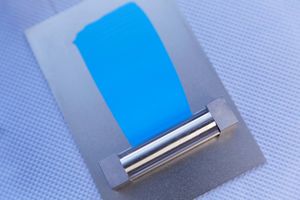

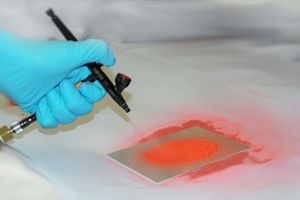

► Adhesive composites for strength tests or climatic stresses - Coating ⇒ applying a strongly adhering layer of formless material (e.g. varnish) to a workpiece e.g. by squeegees, brushes, roller, air brush etc.

Application Examples:

► Test panels for Gcross cutting, gloss level or resistance tests

The manufacture of test specimens can be very complex and maybe involve the combination of several processes. For example, in the production of hybrid injection-molded composite specimens for leakage tests, the processes of cutting/separating (turning the metal insert), coating (applying the adhesive agent to the metal insert) as well as initial forming (polymer injection molding dof the sheath material) and simultaneous joining (thermally activated connection between polymer, adhesive primer and metal insert) are implemented in combination.

Additional Equipment

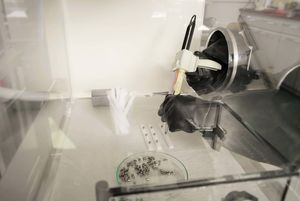

For working under defined atmospheric conditions, a glovebox (65 × 45 × 45 cm) with integrated material lock is available. This allows work to be carried out e.g. under inert gas or to store samples under these conditions. Additionally, the humidity in the box can be regulated between 15 % and 85 % rel. humidity by means of a miniClima Humidity Controll EBC 11. Therefore, investigations, e.g., on the influence of humidity on the curing behaviour of adhesives are enabled.

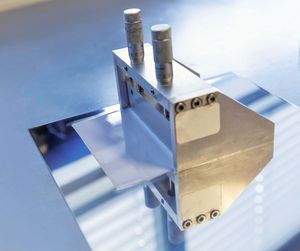

Various coaters (including laminar flow box) and a powder coating installation are available for coating.

Casting processes can be positively influenced by overpressure (against outgassing) or a vibrating table.

⇒ Please do not hesitate to contact us for questions and further information about our R&D and services offered. |

Overview of our Technical Equipment

- 3D Microscope

- Atomic Force Microscopy

- Buchholz Hardness Test

- Coater

- Coating Thickness Measurement

- Colorimeter & Spectrophotometer

- Cross Cutting Test

- Drop Ball Impact Test

- Environmental Test Engineering

- FT-IR (ATR) Spectroscopy

- Gloss Level Analysis

- Grind Gages (Grindometer)

- Irradiation Technology

- Measurement of Corrosion Current

- Mechanochemical Surface Treatment

- Mandrel Bending Test

- Palamat

- Panel Press

- Plastics Technology

- Pneumatic Hot-Melt Dispenser

- Potentiostat / Galvanostat

- Powder Coating

- Raman Spectroscopy

- Sample Preparation Technique

- Scratch & Scribing Tools

- Stirring & Mixing Technique

- TERA Ohmmeter

- Thermal Analysis

- Ultrasonic Testing System

- Universal Testing Machines

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48