Mandrel Bending Test

– with Conical Mandrel –

The mandrel bending test determines a characteristic value for the elasticity, adhesive strength and elongation of a cured coating under bending stress.

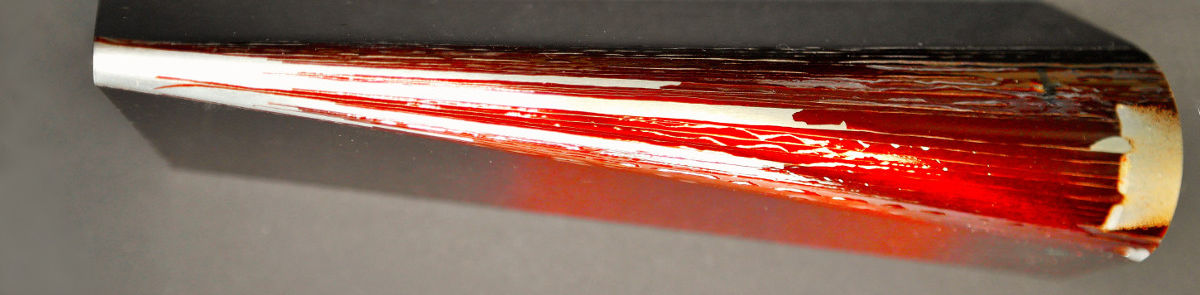

A coated sheet is bent using a lever around a conical mandrel with a diameter of 3.2 to 38.1 mm. The resulting cracks usually start at the thinner end of the mandrel and continue towards the thicker end.

The maximum crack length is read on the scale and the associated mandrel diameter is determined. The size of the bending diameter, where no changes are visible yet, corresponds to the result of the test.

With the conical mandrel bending test, a large range of different bending radii can be recorded within one test.

Testing Standards:

- ASTM D 1737 85

- ASTM D 522

- DIN 53150

- DIN EN ISO 1519

- DIN EN ISO 6860

Application Examples:

- Pretreatment testing

- Quality assessment of primers

- Comparison of curing conditions

- Evaluation of elasticity, adhesive strength and elongation of coatings

- Definition of possible bending radii

- Determination of the mechanical strength of resistant varnishes and similar coatings

⇒ Please do not hesitate to contact us for questions and further information about our R&D and services offered. |

Overview of our Technical Equipment

- 3D Microscope

- Atomic Force Microscopy

- Buchholz Hardness Test

- Coater

- Coating Thickness Measurement

- Colorimeter & Spectrophotometer

- Cross Cutting Test

- Drop Ball Impact Test

- Environmental Test Engineering

- FT-IR (ATR) Spectroscopy

- Gloss Level Analysis

- Grind Gages (Grindometer)

- Irradiation Technology

- Measurement of Corrosion Current

- Mechanochemical Surface Treatment

- Mandrel Bending Test

- Palamat

- Panel Press

- Plastics Technology

- Pneumatic Hot-Melt Dispenser

- Potentiostat / Galvanostat

- Powder Coating

- Raman Spectroscopy

- Sample Preparation Technique

- Scratch & Scribing Tools

- Stirring & Mixing Technique

- TERA Ohmmeter

- Thermal Analysis

- Ultrasonic Testing System

- Universal Testing Machines

Manufacturer:

BYK Gardner GmbH

Model:

5750

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48