Ultrasonic Testing System

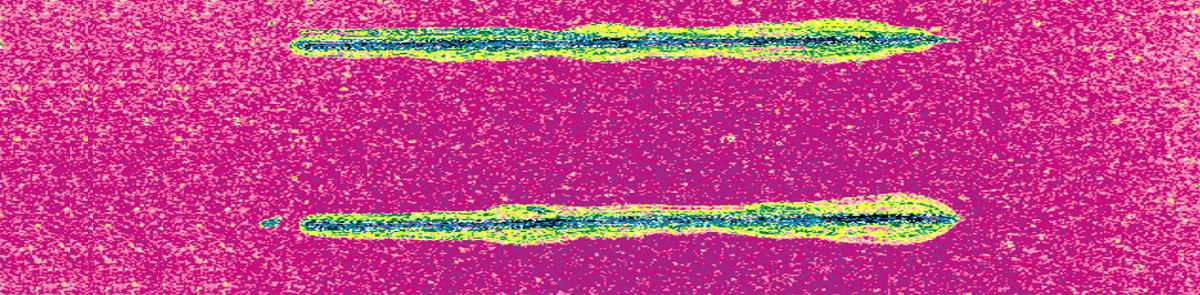

The high frequency (HF) ultrasound device consists of a scanning system with immersion basin, the external transmitter and receiver unit. Using the pulse-echo method, high-resolution interference points are detected on thin samples (depending on the material, up to a maximum of 5 mm) and visualized at the precise location using digital imaging. Among other things, it is used for testing the early damage markers delamination, blistering and rust on varnish layers. Furthermore, adhesion problems in adhesive and fiber composite systems can be detected.

Application Examples

- Non-destructive testing

- Damage analysis of thin components as well as welded and soldered joints

- Detection of incipient corrosion attack on varnish-coated samples in stress test

- Investigation of laminates, fiber, composites, bondings

⇒ Please do not hesitate to contact us for questions and further information about our R&D and services offered. |

Overview of our Technical Equipment

- 3D Microscope

- Atomic Force Microscopy

- Buchholz Hardness Test

- Coater

- Coating Thickness Measurement

- Colorimeter & Spectrophotometer

- Cross Cutting Test

- Drop Ball Impact Test

- Environmental Test Engineering

- FT-IR (ATR) Spectroscopy

- Gloss Level Analysis

- Grind Gages (Grindometer)

- Irradiation Technology

- Measurement of Corrosion Current

- Mechanochemical Surface Treatment

- Mandrel Bending Test

- Palamat

- Panel Press

- Plastics Technology

- Pneumatic Hot-Melt Dispenser

- Potentiostat / Galvanostat

- Powder Coating

- Raman Spectroscopy

- Sample Preparation Technique

- Scratch & Scribing Tools

- Stirring & Mixing Technique

- TERA Ohmmeter

- Thermal Analysis

- Ultrasonic Testing System

- Universal Testing Machines

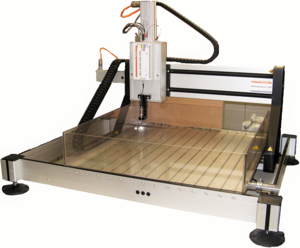

Manufacturer

Ingenieurbüro Dr. Hillger Braunschweig

Model:

USPC 3060 UHF

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48