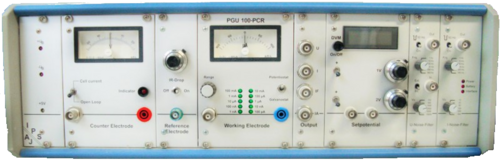

Potentiostat / Galvanostat

The term electrochemical noise is used at corrosion studies to describe the nucleation processes and their healing. These processes correlate to small electrically measurable pulses (events). The analysis methods used are, e.g. event counting, standard deviation or evaluation in the frequency range.

The special feature of measuring electrochemical noise compared to other methods of electrochemical corrosion testing is that the gain in information can be obtained without external excitation of the system (potential noise). The high sensitivity of the test method enables, e.g., the initiation processes of local corrosion phenomena on passive metal surfaces to be determined.

Causes of the electrochemical noise on passive metals are activation and re-passivation processes of the passive layer respectively the hereby caused fluctuations of the charge at the phase boundary interface metal-(passive layer) / electrolyte. Depending on the experimental setup, these charge fluctuations can be measured as noise of current or potential.

Technical Overview:

- Potentiostat, Galvanostat

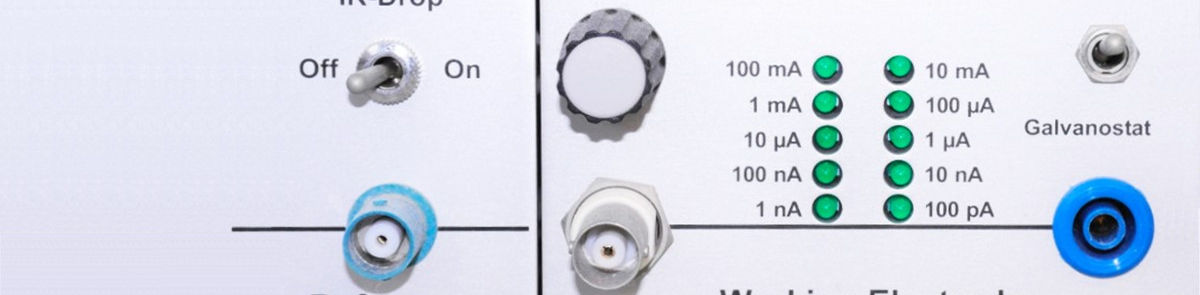

- 10 current ranges: up to 100 pA

- Maximum: ±12 V / ±100 mA

- Resolution: 0,01 pA ( theoretical)

- Instruments for U and I

- Internal nominal voltage generator and 2 nominal voltage inputs

The PGU 100‑PCR is suitable as normal potentiostat / galvanostat as well as for measurement of the electrochemical noise (potential and current noise). The device is equipped with switchable amplifiers for both potential noise (× 100 / 500 / 1000 / 2000 / 5000 / 10000) and current noise (× 10 / 20 / 50 / 100 / 200 / 500). The lower cut-off frequency is permanently set to 0.1 Hz (0.01 Hz). The upper cut-off frequency can be switched in six different ranges (1 / 10 / 40 / 100 / 200 / 500 Hz).

Possible methods and measurements:

- Potential noise

- Current noise (external currentless)

- Both potential‑ and current noise (without external current)

- Current noise under potentiostatic control

- Potential noise under galvanostatic control

⇒ Please do not hesitate to contact us for questions and further information about our R&D and services offered. |

Overview of our Technical Equipment

- 3D Microscope

- Atomic Force Microscopy

- Buchholz Hardness Test

- Coater

- Coating Thickness Measurement

- Colorimeter & Spectrophotometer

- Cross Cutting Test

- Drop Ball Impact Test

- Environmental Test Engineering

- FT-IR (ATR) Spectroscopy

- Gloss Level Analysis

- Grind Gages (Grindometer)

- Irradiation Technology

- Measurement of Corrosion Current

- Mechanochemical Surface Treatment

- Mandrel Bending Test

- Palamat

- Panel Press

- Plastics Technology

- Pneumatic Hot-Melt Dispenser

- Potentiostat / Galvanostat

- Powder Coating

- Raman Spectroscopy

- Sample Preparation Technique

- Scratch & Scribing Tools

- Stirring & Mixing Technique

- TERA Ohmmeter

- Thermal Analysis

- Ultrasonic Testing System

- Universal Testing Machines

Manufacturer:

IPS Elektroniklabor GmbH

Model:

PGU-100PCR

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48