Sol-Gel Technology

In addition to flame treatment and plasma processes, sol-gel technology is another important part of the atmospheric pressure based coating processes at INNOVENT.

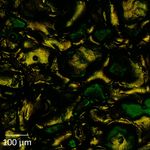

Depending on the precursors used, non-metallic inorganic or hybrid polymer layers can be applied to various materials, such as: glass, metal, textiles, and plastics using a sol-gel process from colloidal dispersions. By embedding the smallest inorganic or organic particles in the layers, additional functionalities such as scratch resistance, fluorescence properties or antibacterial effect can be achieved.

In addition to common coating processes such as dipping, spraying and doctoring, INNOVENT uses a laboratory coating plant for wet film application. This allows for a large-area, high-quality application of functional layers in the nanometer range on flat substrates, such as glass or flexible roll materials (e.g. films, textiles). The layers are applied by means of a slot nozzle or a spray application. A corona pretreatment is also possible for roll goods.

By combining sol-gel technology with various atmospheric pressure and vacuum-based processes, special functionalization and adhesive strength can be achieved. Thus, the long-term durability can be improved.

As a result of these various possibilities, a wide range of applications can be developed using sol-gel processes with regard to:

- Protection against plagiarism

- Corrosion protection layers

- Barrier layers

- Bactericidal layers

- Photocatalytically active layers

- High-temperature resistant coatings

- Layers to reduce adhesion

- Scratch-resistant coatings

Projects

Current projects

- Functional sol-gel coatings, for optimizing the demoulding behavior of moulded parts from injection moulds

- Development of sol-gel systems, for the replication of micro and nanostructures with improved properties

- Investigation and optimization of the drying and curing behavior of sol-gel coatings on roll stock, by means of process combination

- Method for objective evaluation of edge deletion

- Surface adaptation for marine coatings using basalt flock

- Bonding layers and active edge seals, for basalt fiber composite optical components

Completed projects

- Antibacterial and anticorrosive easy-to-clean coatings, for glass surfaces in wet areas

- Development of a coating technology, for the production of highly corrosion-resistant powder-coated 3D components made of steel and galvanized steel

- Development of a transparent structurable plagiarism protection, on the basis of coatings containing fluorescent dyes and nanoparticles

- EHOS - Functional sol-gel systems with release effect, for the coating of plastic processing tools

- Plasma-assisted photocatalytic water purification (PlaPhoWa)

Team Chemical Technologies

The chemical technologies team combines the expertise of chemists, materials scientists and materials engineers.

Dr. Tina Toelke

Surface Technology

Team Leader

Chemical Technologies

e-mail

Phone: +49 3641 282554