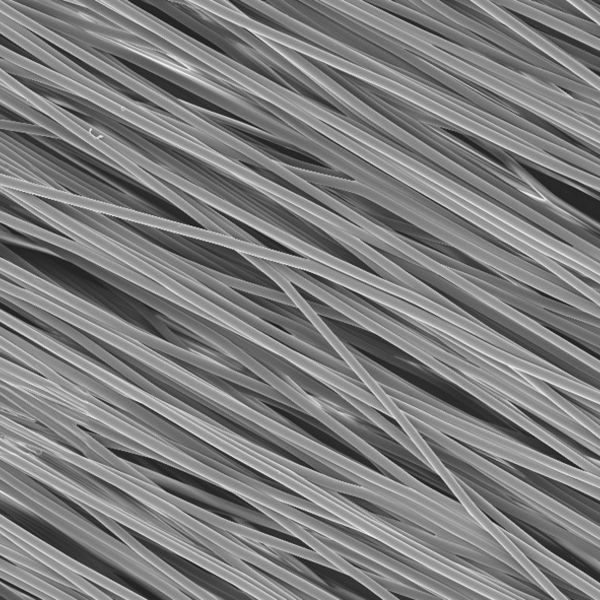

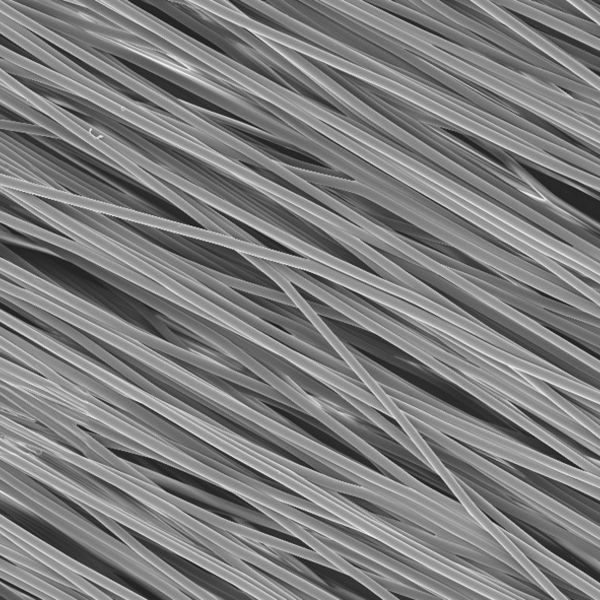

BMA-001 Electrospinning

The technology of electrospinning allows the production of nano- and microfibers and fleeces made of different materials.

Reference No. BMA-001

The technology of electrospinning allows the production of nano- and microfibers and fleeces made of different materials.

Reference No. BMA-001

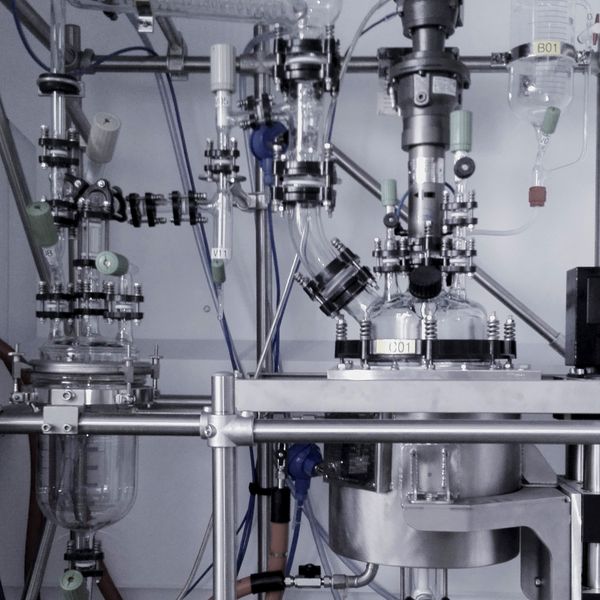

INNOVENT transfers your laboratory synthesis to industrial scale, and carries out process optimization and custom synthesis for you.

Reference No. BMA-002

The targeted chemical modification of glycosaminoglycans (e.g. hyaluronic acid, chondroitin sulfate, heparin) offers access to new biomaterials with…

Reference No. BMA-003

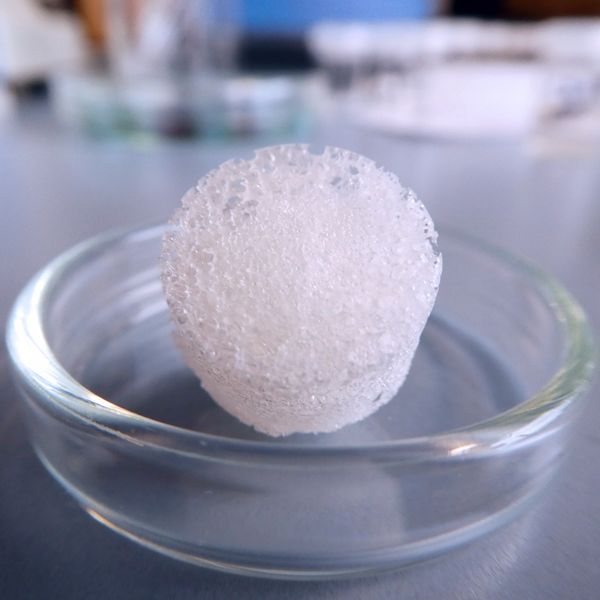

The synthesis of biocompatible and biodegradable polyurethanes and polyureas is a focus of research in the department of Biomaterials.

Reference No. BMA-004

INNOVENT offers the development of suitable coating solutions and layer systems according to the application purpose and the required properties.

Reference No. OFT-010

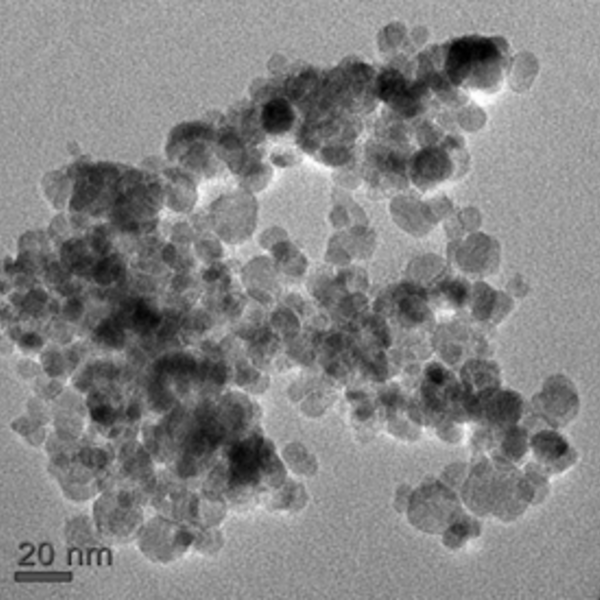

The production of functionalized nanoparticles enables new approaches to the targeted modification of materials.

Reference No. OFT-011

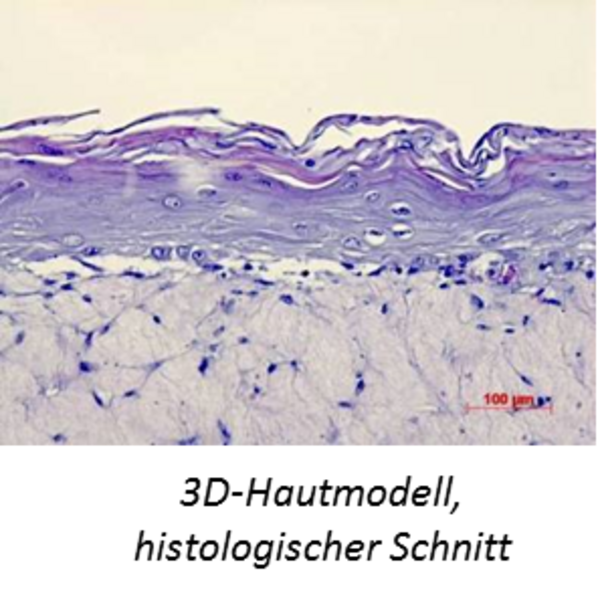

The application of plasma sources in dermatology opens a new field of healing, desifention and antibacterial equipment.

Reference No. OFT-012

Titanium oxide (TiOx) coatings are photocatalytically active when exposed to UV radiation, i.e. radicals are formed which decompose organic…

Reference No. OFT-013

Surface treatment technologies offer possibilities to provide functional coatings directly on the material surface.

Reference No. OFT-015

INNOVENT tests and analyses organochlorine compounds, and uses atmospheric pressure plasma to clean untreated wood surfaces.

Reference No. OFT-016

The investigation on the deposition of SnOx coatings shows a favorable sensor activity of the layers.

Reference No. OFT-017

Due to its low thermal influence, APCVD also allows the treatment of temperature-sensitive materials such as textiles.

Reference No. OFT-019

Optimized treatment parameters in the gas phase fluorination of silicones is reflected, according to the motto: As much effect as possible with as…

Reference No. OFT-020

A combination of C-CVD and sol-gel technology can be used to produce relatively thin, flexible and smooth coating systems.

Reference No. OFT-022

The application on textiles allows for the removal of disturbing textile additives, as well as a new finishing with suitable substances.

Reference No. OFT-023

In order to optimize bonded joints, surface activations are applied and adapted to the adhesive and the substrate to be joined.

Reference No. OFT-024

The application of a targeted surface activation enables the creation of particularly adhesive powder coating layers on glass surfaces.

Reference No. OFT-025

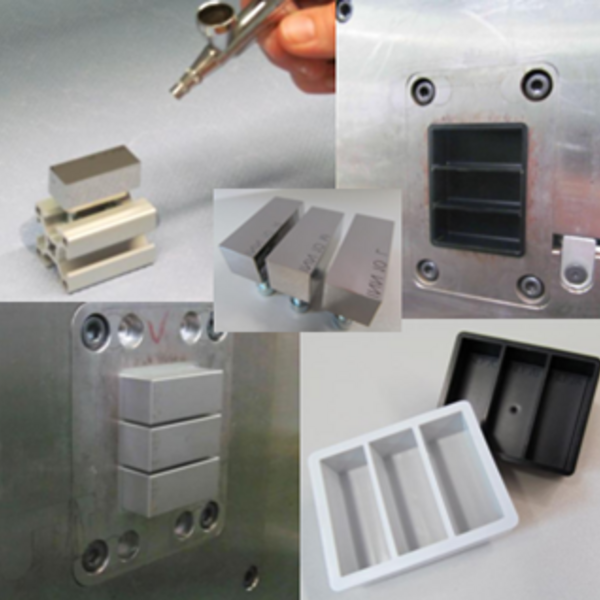

The sol-gel coatings developed to date, work excellently for molded parts with simple geometries.

Reference No. OFT-026

With the use of sol-gel technology, it is possible to produce non-metallic inorganic or hybrid polymeric coatings.

Reference No. OFT-027

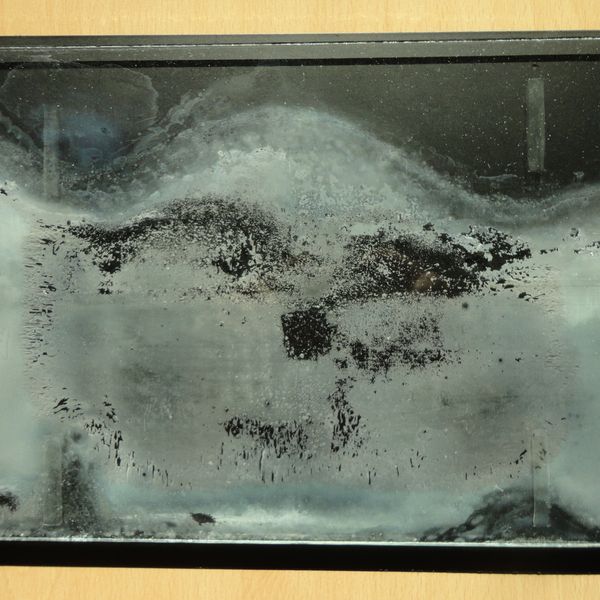

A process combination of wet-chemical pretreatment and sol-gel corrosion protection coating with subsequent powder coating is a powerful tool against…

Reference No. OFT-028

Using a combination of processes based on atmospheric pressure, it is possible to produce corrosion-resistant, easy-to-clean and antibacterial…

Reference No. OFT-029

AD plasmas offer a wide range of application possibilities, which can be used universally for almost all material classes.

Reference No. OFT-030

The hydrophobic layer is completely free of fluorine: only a few nanometers thin and abrasion resistant on glass-like substrates according to ASTM…

Reference No. OFT-031

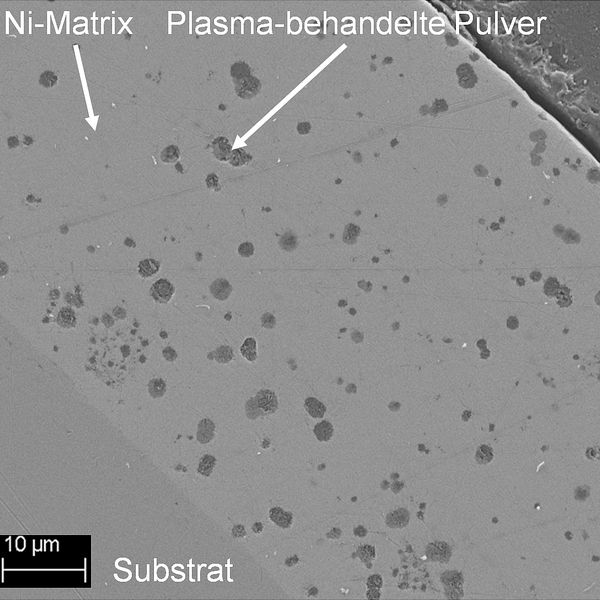

Up to now, surfactants and dispersants containing fluorine have often been used in nickel electrolytes. Their use is subject to strict restrictions…

Reference No. OFT-032

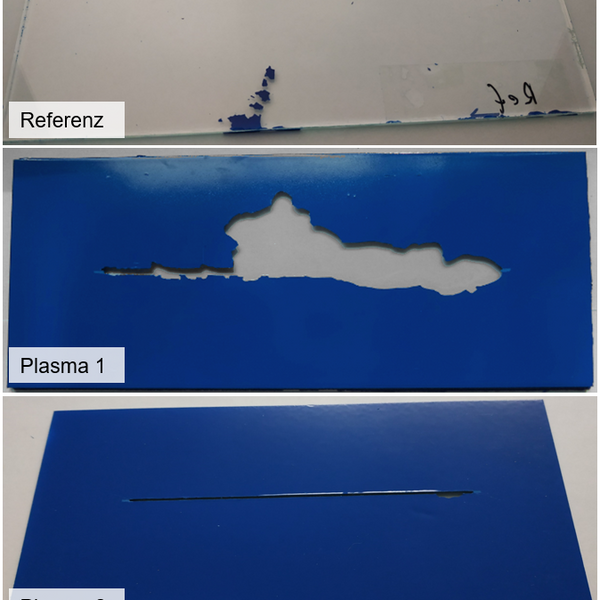

Plasma pretreatment of laminated safety glass can increase important properties such as break resistance by up to 60% (compared to standard laminated…

Reference No. OFT-033

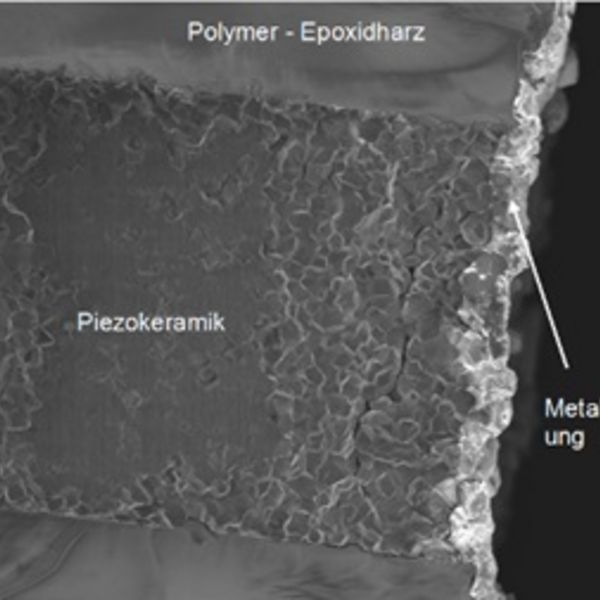

Through the use of plasma techniques it is possible to avoid the use of pickling solutions and aggressive chemicals for the metallization of plastics.…

Reference No. OFT-034

Technology offer for the industrial sectors analytics, energy, medical technology, automotive, life science

Reference NO.: OFT-035

Dr. Bernd Gruenler

Director

e-mail

Phone: +49 3641 282510