Stirring & Mixing Technique

The available stirring and mixing technology allows us to optimally stir, mix and disperse adhesives, sealants, casting coumpounds, paints and varnishes on a laboratory scale. The processable product quantities start at about 0.5 g. During the processes, reproducible homogeneous mixtures are created. Due to the special procedures, it is possible to obtain bubble-free preparations or to degas products in a targeted manner.

Speedmixer

| Manufacturer: | Hauschild Engineering |

| Type: | Speedmixer DAC 150 FVZ |

The speedmixer is a laboratory mixing system, which is ideally suited for quick mixing, dispersing or grinding of different materials due to the double rotation of the mixing cup (principle ⇒ "dual asymmetrical centrifuge"). Reproducible results are achieved within a short time. The speedmixer is preferred for the production of bubble-free homogeneous mixtures of adhesives, sealants / casting compounds and paints / varnishes. The used liquid raw materials can range from low to high viscosity or even be kneadable. When adding fillers such as powder, fibers, flakes, high filling levels can be achieved.

Device Configuration

- Speed range: from 300 to 3500 rpm

- Mixing times: starting at 5 s

- Quantity: from approx. 0.5 g

Application Examples:

- Mixing, dispersing and grinding

- Mixtures

• Bubble-free

• Homogeneous

• Reproducible

- For low to high viscosity / kneadable components

- High filler contents can be realized

Especially Suitability for:

adhesives, sealants, casting compounds, paints and varnishes

Dispersants / Dissolver / Mixer

| Manufacturer: | VMA Getzmann GmbH | IKA Labortechnik |

| Type: | Dispermat CA 40 | Dispergator T25 basic and Rührgerät IKA Eurostar |

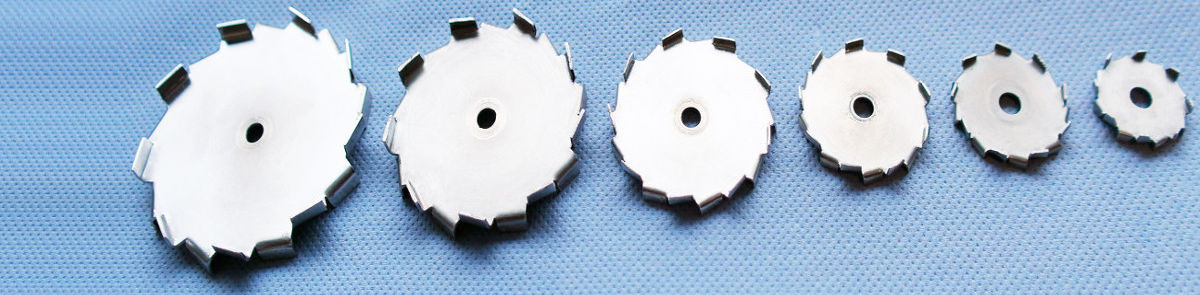

Dissolvers are disk stirrers, which are used for dispersion. For example, in this process a pigment powder is dispersed in a binder, whereby the dissolver has the function of breaking up agglomerates of primary particles.

A vertical stirrer shaft is equipped with a toothed stirring disc (dispersing disc), which is dipped into the product to be dispersed. Due to the fast rotating movement of the dispersing disk and the resulting shear forces, the agglomerates are dispersed.

Device Configuration

- Speed range: 0 to 20,000 rpm or 0 to 24,000 rpm

- Stainless steel container: 100, 250 & 500 ml

- Dispersing discs: 25, 30, 40, 50, 60 & 80 mm made of stainless steel

- Accessories: vacuum unit up to 250 ml + clamping unit

- Quantity: from 0.05 l

As additional equipment, a temperature-controlled vacuum system is available. Using this supplementary system, highly viscous products can be dispersed and degassed simultaneously. Furthermore, the dissolver is equipped with a container-clamping unit, which also enables dispersing in various containers (bottles, cups, hobbocks).

⇒ Please do not hesitate to contact us for questions and further information about our R&D and services offered. |

Overview of our Technical Equipment

- 3D Microscope

- Atomic Force Microscopy

- Buchholz Hardness Test

- Coater

- Coating Thickness Measurement

- Colorimeter & Spectrophotometer

- Cross Cutting Test

- Drop Ball Impact Test

- Environmental Test Engineering

- FT-IR (ATR) Spectroscopy

- Gloss Level Analysis

- Grind Gages (Grindometer)

- Irradiation Technology

- Measurement of Corrosion Current

- Mechanochemical Surface Treatment

- Mandrel Bending Test

- Palamat

- Panel Press

- Plastics Technology

- Pneumatic Hot-Melt Dispenser

- Potentiostat / Galvanostat

- Powder Coating

- Raman Spectroscopy

- Sample Preparation Technique

- Scratch & Scribing Tools

- Stirring & Mixing Technique

- TERA Ohmmeter

- Thermal Analysis

- Ultrasonic Testing System

- Universal Testing Machines

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48

![[Translate to English:] Dispergator with container clamping device and temperature-controlled vacuum system The illustration shows a disperser with container clamping device and temperature-controlled vacuum system in operation.](/fileadmin/_processed_/d/1/csm_G14_2_Dispergator2b_5519c89f44.jpg)