Nozzles

- Round string nozzle: Ø 3 mm

- Wide slot nozzle : 30 mm × 1 - 3 mm

- Wide slot nozzle with flex lip: 150 mm × 0.2 - 2 mm

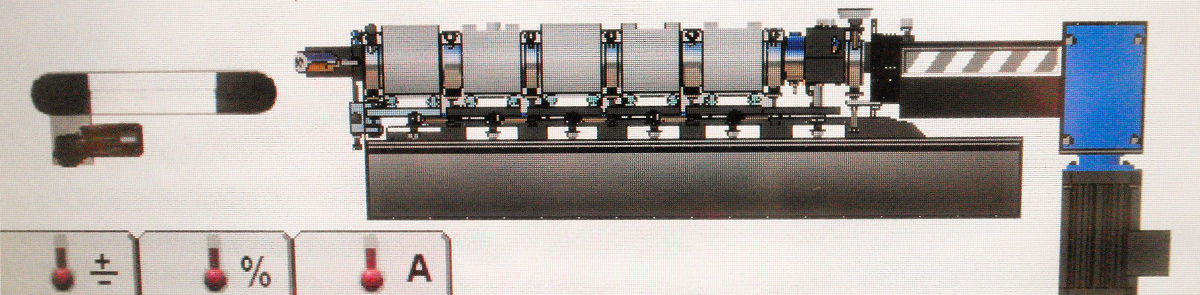

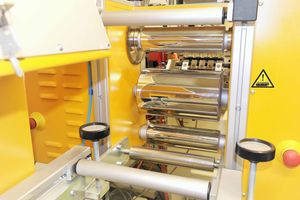

Flat film line 3-Roll Chill Roll (CR136/230)

- Film width: 230 mm

- Temperature adjustable

- Switchable smoothing roller with variable contact pressure: 20 - 80 N/cm

- Haul-off speed up to 5 m/min

Air cooling conveyor

- adjustable

- Teflon-coated conveyor belt (length: 1500 mm, width: 150 mm)

- Cooling by 5 compressed air nozzles

Water bath

- Incl. deflection and guide rollers

- Length: 1000 mm, cooling path can be extended by 3-fold deflection

- Compressed air round nozzle for string drying

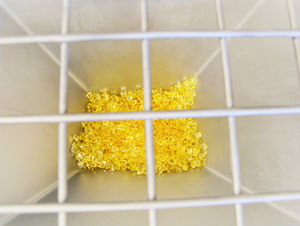

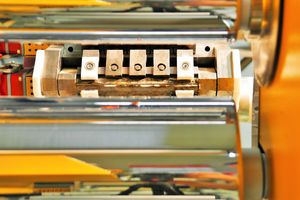

String pelletizing line (type CSG 171/2)

- Haul-off speed: 5 - 70 m/min

- Granulate length: 0.8 - 5 mm

Technical Data

| Specifications | |

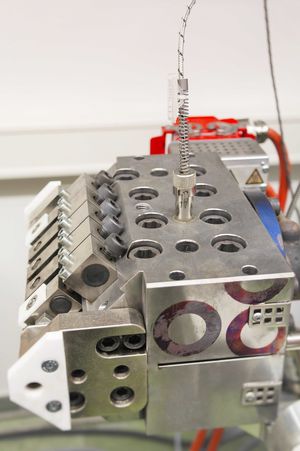

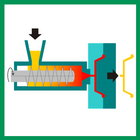

| Screw diameter | 16 mm |

| Length | 36D |

| Speed range | 0 - 500 U/min |

| max. working temperature | 400 °C |

| Main dosing | 0.1 - 3 kg/h (volumetric) |

| Secondary dosing | 0.15 - 3 dm³/h (gravimetric) |

| Side feeding system for secondary dosing | with 14 mm twin-screw system |

| Liquid dosing | 0.5 - 8 cm³/min - heatable up to 100 °C |

| Degassing | free degassing or degassing under vacuum possible |

Overview of our Technical Equipment

- 3D Microscope

- Atomic Force Microscopy

- Buchholz Hardness Test

- Coater

- Coating Thickness Measurement

- Colorimeter & Spectrophotometer

- Cross Cutting Test

- Drop Ball Impact Test

- Environmental Test Engineering

- FT-IR (ATR) Spectroscopy

- Gloss Level Analysis

- Grind Gages (Grindometer)

- Irradiation Technology

- Measurement of Corrosion Current

- Mechanochemical Surface Treatment

- Mandrel Bending Test

- Palamat

- Panel Press

- Plastics Technology

- Pneumatic Hot-Melt Dispenser

- Potentiostat / Galvanostat

- Powder Coating

- Raman Spectroscopy

- Sample Preparation Technique

- Scratch & Scribing Tools

- Stirring & Mixing Technique

- TERA Ohmmeter

- Thermal Analysis

- Ultrasonic Testing System

- Universal Testing Machines

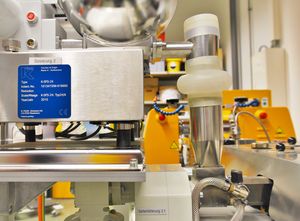

Manufacturer:

Dr. Collin GmbH

Model:

ZK 16 E x 36

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48