Plastic Injection Molding

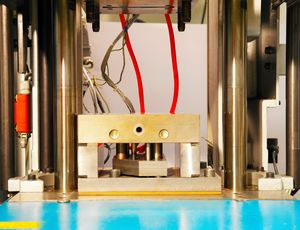

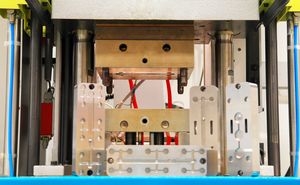

For the production of test samples and material composites, an industrial injection molding machine with various temperature-controlled tools and inserts is available. The tools can be tempered electrically or by means of liquid.

The use of suitable customer tools is also possible. In the case of special requirements or tasks, the production of appropriate tools by external cooperation partners is usual.

Separate injection units are also available for processing elastomers and highly filled plastics.

Special Feature: The design of the injection molding machine with vertical clamping unit and vertical injection is ideal for processing inserts into molded hybrid composites.

The fixed lower mold tool prevents the inserts from slipping during the clamping process.

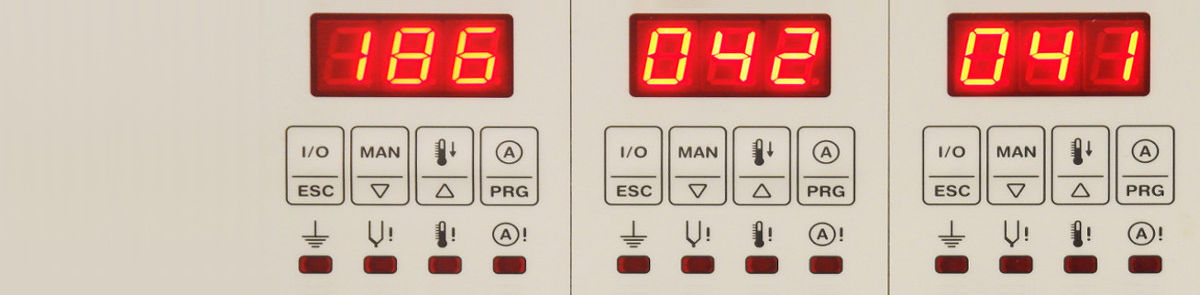

Technical Data:

| Specifications | |

|---|---|

| Closing force | 220 kN |

| Distance between plates | 400 mm |

| Mold opening distance | max. 200 mm |

| Clear width between the spars | 254 mm |

| Theoretical max. shot weight (PS) | 57 g |

| Screw diameter (default) | 22 mm (max. shot weight (PS) 27 g) |

| Max. working temperature | 400 °C |

| Hydraulically operated valve gate nozzle | |

| Additional Equipment | |

| Elastomer unit | 22 mm |

| Armored screw / cylinder | 22 mm |

Overview of our Technical Equipment

- 3D Microscope

- Atomic Force Microscopy

- Buchholz Hardness Test

- Coater

- Coating Thickness Measurement

- Colorimeter & Spectrophotometer

- Cross Cutting Test

- Drop Ball Impact Test

- Environmental Test Engineering

- FT-IR (ATR) Spectroscopy

- Gloss Level Analysis

- Grind Gages (Grindometer)

- Irradiation Technology

- Measurement of Corrosion Current

- Mechanochemical Surface Treatment

- Mandrel Bending Test

- Palamat

- Panel Press

- Plastics Technology

- Pneumatic Hot-Melt Dispenser

- Potentiostat / Galvanostat

- Powder Coating

- Raman Spectroscopy

- Sample Preparation Technique

- Scratch & Scribing Tools

- Stirring & Mixing Technique

- TERA Ohmmeter

- Thermal Analysis

- Ultrasonic Testing System

- Universal Testing Machines

Manufacturer:

Dr. Boy GmbH

Model:

Boy 22 MVV

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48