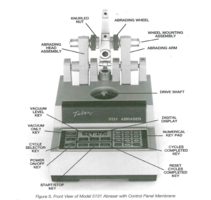

Device configuration:

- Rotary table for square or round samples, 1 revolution / s (constant)

- Ø 7 mm through-hole at the sample center

- Sample thickness: 1 mm to max. 8 mm

- Square samples: 100 x 100 mm²

- Round samples: Ø 100 mm to max. 140 mm

- Abrasion using Calibrase and Calibrade rolls or rubber roll with self-adhesive sandpaper strips S 42

- Rubber roll: CS0

- Calibrase rolls: CS10, CS10F, CS17

- Calibrade rolls: H10, H18

- Removal of abrasion using integrated suction unit

- Additional weights: 250 g, 500 g, 750 g, and 1000 g

- Four-Point Measurement of Resistance

- Abrasion Resistance

- Flame Treatment Units

- CGME – Controlled Growth Mercury Electrode

- Digital Microscope

- ECMC – Electrochemical MiniCell

- EDX-Analysis

- Planar Plasma Sources

- Fluorination

- FTIR Spectroscopy

- GDP-C

- Cross-Cut Tester

- Grey Scale Measurement

- Gravimetric Titrator – Alino®

- Hardness Tester

- Hardness and Micro Hardness Testing

- Infrared Camera - Vario THERM

- Infrared Thermometer (Pyrometer)

- Jet Plasmas

- Confocal Microscope

- Laboratory Electroplating

- Lacquer Testing Device Carving Graver

- Conductivity Measurement for Non-Ferrous Metals

- Optical Microscope Leica DMi8 C

- Mastersizer

- Optical Emission Spectrometer

- pH Value Determination

- pH/Conductivity Meter

- Plasma Polymerization

- Potentiostat / Galvanostat / ZRA

- Contact Angle Measuring Instrument

- Scanning Electron Microscope (SEM)

- Atomic Force Microscope (AFM)

- Roughness

- Rheometer MCR 301

- Rheometer MCR 502 TDR

- Scratch Hardness Tester

- X-Ray Fluorescence Unit Fischerscope

- X-Ray Photoelectron Spectrometer XPS

- Admittance

- Coating Thickness Gauge MiniTest 4100

- Coating Thickness Gauge Quint Sonic

- Sol-Gel Unit

- Spectral Ellipsometer SE850

- Sputter Technology

- Stylus Instrument / Profilometer Alpha-Step D-600

- Stylus Instrument / Profilometer PGI1200

- Thermal Evaporation

- Universal Testing Machine

- UV/VIS Spectrometer

- UV-VIS Spectroscopy

- Wear Test

- Videoextensiometer RTSS

- Xenon Arc Test

- Zeta Potential Measurement

Manufacturer:

Taber Industries

(Distributed via Erichsen GmbH)

Model:

Taber-Abraser 5131

Adrian Würzl

Surface Technology

e-mail

Phone: +49 3641 282517