Infrared Laser

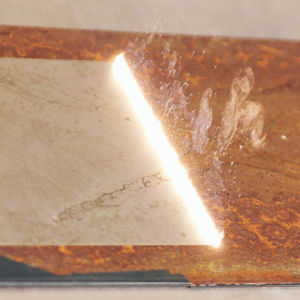

The infrared Laser type CL100 fabricated by CleanLaser is mainly marketed for cleaning procedures. In the industrial sector, the laser is preferably utilized for decoating, de-painting and cleaning works. Furthermore, it is partially suitable for structuring and labeling.

The operating principle is based on the evaporation of dirt and/or top layers by the focused laser beam. At appropriate process parameters, the high power but simultaneously short laser pulses cause only a very low thermal load on the base material.

In addition to the known ones, INNOVENT is investigating the following fields of application:

- Laser based silicatization

- Chemical surface modification of non-laser-sensitive polymers

Due to the computer-controlled 2D scanning head, a high spatial resolution can be realized. Depending on the selected objective, the resolution is in the range of the focus diameter. The smallest possible image is a dot of about 55 µm. All geometric images respectively structures are created by combining single pixels.

Overview of our Technical Equipment

- 3D Microscope

- Atomic Force Microscopy

- Buchholz Hardness Test

- Coater

- Coating Thickness Measurement

- Colorimeter & Spectrophotometer

- Cross Cutting Test

- Drop Ball Impact Test

- Environmental Test Engineering

- FT-IR (ATR) Spectroscopy

- Gloss Level Analysis

- Grind Gages (Grindometer)

- Irradiation Technology

- Measurement of Corrosion Current

- Mechanochemical Surface Treatment

- Mandrel Bending Test

- Palamat

- Panel Press

- Plastics Technology

- Pneumatic Hot-Melt Dispenser

- Potentiostat / Galvanostat

- Powder Coating

- Raman Spectroscopy

- Sample Preparation Technique

- Scratch & Scribing Tools

- Stirring & Mixing Technique

- TERA Ohmmeter

- Thermal Analysis

- Ultrasonic Testing System

- Universal Testing Machines

Manufacturer:

cleanLASER GmbH

Model:

CL100

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48