VUV Systems

VUV refers to a particularly short-wave part of the UVC spectrum. Our research is primarily focused on the development of practical process solutions using short-wave UVC light for surface treatment and exploring potential fields of application.

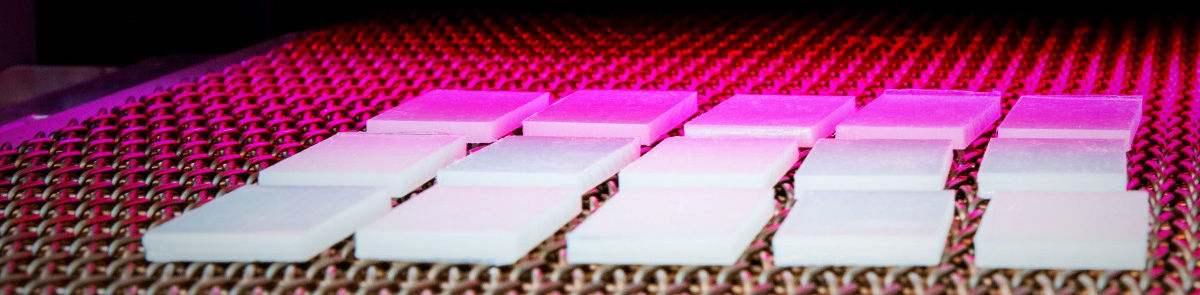

A versatile and uncomplicated convertible testing technique was developed, which can be operated with different light sources and optionally as a closed chamber or as an open unit in continuous throughput process. Treatment parameters, which are relevant for manufacturing, can be varied and reproducibly adjusted. The VUV treatment can be performed under air ambient conditions or by adding other process gases such as inert gas, nitrogen or precursor formulations.

For developing and testing of new methods as well as for the further development of these methods for new applications, various UVC light sources with different emission wavelengths are available:

Xe Excimer

| Manufacturer: | Osram/Ledvance |

| Model: | XIS 375x96 |

The operating principle of the Excimer – excited dimer, is the excitation of a metastable state to form a noble gas molecule during whose disintegration light of a specific wavelength is emitted.

Our system works with xenon as the operation gas. With emitted wavelength of 172 nm, almost all organic substances can be cracked, which makes this irradiation system interesting for many surface cleaning and activation applications.

Application Examples

- Cleaning of technical surfaces (e.g. glasses, steel, ceramics)

- Activation of polymers for adhesive bonding and coating, etc.

- Functionalization of polymer surfaces

- Hydrophilization

Device Configuration

- Power input: max. 330 Watt

- Irradiation power: adjustable up to max. 40 mW/cm²

- Height adjustment: 0 to 100 mm

- Irradiation width: max. 38 cm

- Stationary and conveyor operation possible

- Conveyor speed: 5 to 200 cm/min

Low Pressure Hg Lamp System

| Manufacturer: | Groebel UV |

| Model: | custom-built fabrication |

The low pressure mercury amalgam lamps installed in our irradiation system emit a spectrum with two main lines at 185 and 245 nm. At wavelengths below 200 nm, light can transform oxygen into ozone.

In combination with the emitted irradiation, these reactive oxygen species are able to clean surfaces of polymers and break bonds in polymer molecules. In contrast to the 172 nm excimer unit, the working distance can be varied more freely, which also allows the treatment of non-planar sample structures.

Application Examples

- Cleaning of technical surfaces (e.g. glasses, steel, ceramics)

- Activiation of polymers for adhesive bonding and coating, etc.

- Functionalization of polymer surfaces

- Hydrophilization

Device Configuration

- Operation settings:

- Power input: 385 W

- Lamps: 11; separately switchable

- Maximum intensity: at 185 nm → 8 mW/cm²

- Maximum intensity: at 254 nm → 50 mW/cm²

- Irradiation width: max. 38 cm

- Irradiation distance: adjustable to 16 cm

- Stationary and conveyor operation possible

- Conveyor speed: 5 to 200 cm/min

Excimer Laser

| Manufacturer: | ATL/Optec |

| Model: | custom-built fabrication |

In contrast to the UVC lamps available in our house, this excimer laser emits coherent light with a single defined, narrow banded wavelength.

The used laser is a pulsed argon fluoride (ArF) laser manufactured by ATL. It can be operated with variable pulse frequency and has three switchable optical systems, which allows setting for a wide fluence range. With this system, our in-house facilities for treatment technical surfaces with VUV irradiation are optimally supplemented.

Application Examples

- Cleaning of technical surfaces (e.g. glasses, steel, ceramics)

- Activiation of polymers for adhesive bonding and coating, etc.

- Functionalization of polymer surfaces

- Hydrophilization

Device Configuration

- Operation settings:

- Frequency: 1 - 500 Hz

- Pulse energy: 3 - 10 mJ

- Adjustable fluence: 3 - 160 mJ/cm² (single pulse)

- 3 switchable optical systems

- Motorized x-y stage for irradiation of areas up to approx. 30 × 20 cm²

- Software-assisted irradiation for precise setting of fluence with high spatially resolution

Overview of our Technical Equipment

- 3D Microscope

- Atomic Force Microscopy

- Buchholz Hardness Test

- Coater

- Coating Thickness Measurement

- Colorimeter & Spectrophotometer

- Cross Cutting Test

- Drop Ball Impact Test

- Environmental Test Engineering

- FT-IR (ATR) Spectroscopy

- Gloss Level Analysis

- Grind Gages (Grindometer)

- Irradiation Technology

- Measurement of Corrosion Current

- Mechanochemical Surface Treatment

- Mandrel Bending Test

- Palamat

- Panel Press

- Plastics Technology

- Pneumatic Hot-Melt Dispenser

- Potentiostat / Galvanostat

- Powder Coating

- Raman Spectroscopy

- Sample Preparation Technique

- Scratch & Scribing Tools

- Stirring & Mixing Technique

- TERA Ohmmeter

- Thermal Analysis

- Ultrasonic Testing System

- Universal Testing Machines

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48