Hydrophilization

Hydrophile (ancient Greek) - Water loving

Surfaces are described as hydrophilic if the contact angle with water is smallest as possible, ideally at 0°. A drop of water on a hydrophilic surface spreads, i.e. it runs wide and wets the surface.

Hydrophilic surfaces can be created by physical methods, such as plasma treatment, or chemical methods, e.g. through surface reactions or the application of a hydrophilic coating.

An important field of application of hydrophilizing surface treatments in practice is improving the wettability of surfaces with respect to water used as a pretreatment for homogeneous and adhesive coatings, varnishes or adhesives.

By using a laser , the surfaces can be cleaned of various materials. This cleaning effect in an air atmosphere already leads to a reduction of the contact angle, especially with metals such as stainless steel or titanium. If the cleaning is additionally carried out in a silicating liquid, the surface is functionalized or in particular silicated in combination to the normal cleaning effect. This silicatization leads to a very good hydrophilization of the surface. You can find more about our silicatization processes here. At the same time, silicatization is very well suited as a basis for bonding. More information about bonding processes and techniques can be found here.

Spatially resolved hydrophilization utilizing laser technology is preferably used for materials that are not transparent in the wavelength range of laser irradiation (approx. 1064 nm).

Advantages of this Technology:

- Spatially highly resolved hydrophilization

- Complex structures are possible

- Smallest structure approx. 55 µm (spot diameter of the laser beam)

- Maximum treatment area 28 × 28 cm (without additional movement - with additional movement the treatment area is theoretically unlimited)

- Low temperature load due to the simultaneous cooling effect of the bath

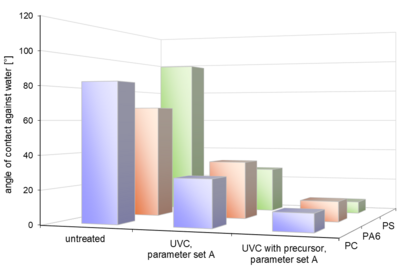

The application of short-wave UVC light is a modern, versatile, expandable and automatable method to provide surfaces of originally hydrophobic plastics with hydrophilic properties in a gentle and clean way (no use of aggressive chemicals, no waste products). The physicochemical basis for this are photonically initiated splitting and reattachments of bonds on surface structures. The formation of polar/hydrophilic surface properties after UVC treatment in the presence of oxygen (e.g. in air) is mainly attributed to the attachment of oxygen degradation products to activated species of the plastic surface. Due to the strong absorption of UVC light < 200 nm through almost all plastics, a very small penetration depth of the radiation into the respective bulk material is guaranteed, so that the effect of the UVC light on the material surface is limited.

The method can be applied to a wide range of plastic types with different base polymers. Appropriate UVC research equipment is available for trials and testing with specific issues. In order to achieve the best possible hydrophilization results for specific tasks, the treatment parameters can be adapted to the respective material and especially to the composition of the surface.

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48