Primer & Adhesive Agents for

Bonding Processes

For bonding applications, primers and adhesive agents have the primary function of creating and ensuring sufficient adhesion for the respective purpose. On the one hand, this includes the creation of a strong adhesion to the substrate and, on the other hand, the realization of a firm bond to the adhesive. This adhesion-promoting effect should also be maintained under the usual environmental influences (temperature, media, etc.), which the composite is exposed.

Primers for adhesive applications do not have a uniform chemical nature, but rather are chemically very diverse and are formulated, selected and used in accordance with the function to be fulfilled.

For example, it is a matter of:

- Thin (co-)polymer layers

- Systems based on silicon, titanium or zirconium compounds

- Formulations with other functions that are especially adapted to the specific case

It is fundamental that the primer system has the appropriate functionality for the specific application in order to complete its tasks.

For good adhesion to metals, it is usually beneficial if the primers / adhesive agents have a specific chelating function to "bite" into the coordination sphere of the metal atoms.

Surfaces with reactive OH groups can often be firmly bonded with formulations of silane coupling agents. For the bonding of polyolefins with cyanoacrylates, activating primers are usually weakly basic substances (e.g. amines, phosphines), which penetrate into near-surface hollow spaces, promote the wetting with cyanoacrylate and initiate the anionic polymerization. This results in firmly adhering "push-button composites".

Primers must always be considered, selected and/or formulated in the context of the overall requirements for the adhesive bond, this comprise the substrate (including its pretreatment), the adhesive, the application profile of the adhesive composite and the technical production conditions. The developed adhesive agency can be performed as a separate application as part of the surface pretreatment or can function as a proportionate component of the adhesive formulation.

Besides purely chemical adhesion promoting processes, physical techniques such as silicatization, mechanochemical surface treatment or modification of the wettability of substrate surfaces can also be used to improve the adhesion.

We are pleased to support you in the selection, formulation and application of primers for your bonding application and are available for your questions and comments.

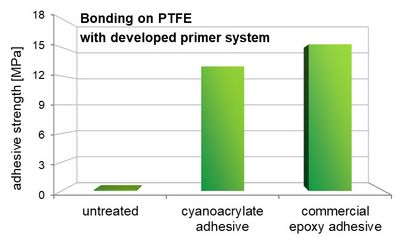

Adhesive Bonding of PTFE (Teflon)

With the developed technology comprising primer and adjusted application technique, a shear strength of the bonded samples (e.g. of Teflon and steel) can be achieved close to the inherent strength of PTFE. Depending on the used adhesive, one or two pretreatment steps are required.

Advantage:

- PTFE surface coating is permanently applied even on large surfaces

- No usage of "hard" chemistry

- Pretreatment can be carried out under "normal" environmental conditions

- With subsequent bonding, the application of commercial adhesives is possible

- Developed primer system is less environmentally harmful

- After finished reaction of the primer system, the composite is harmless to health

The developed primer system is also suitable for bonding silicones with cyanoacrylate adhesives.

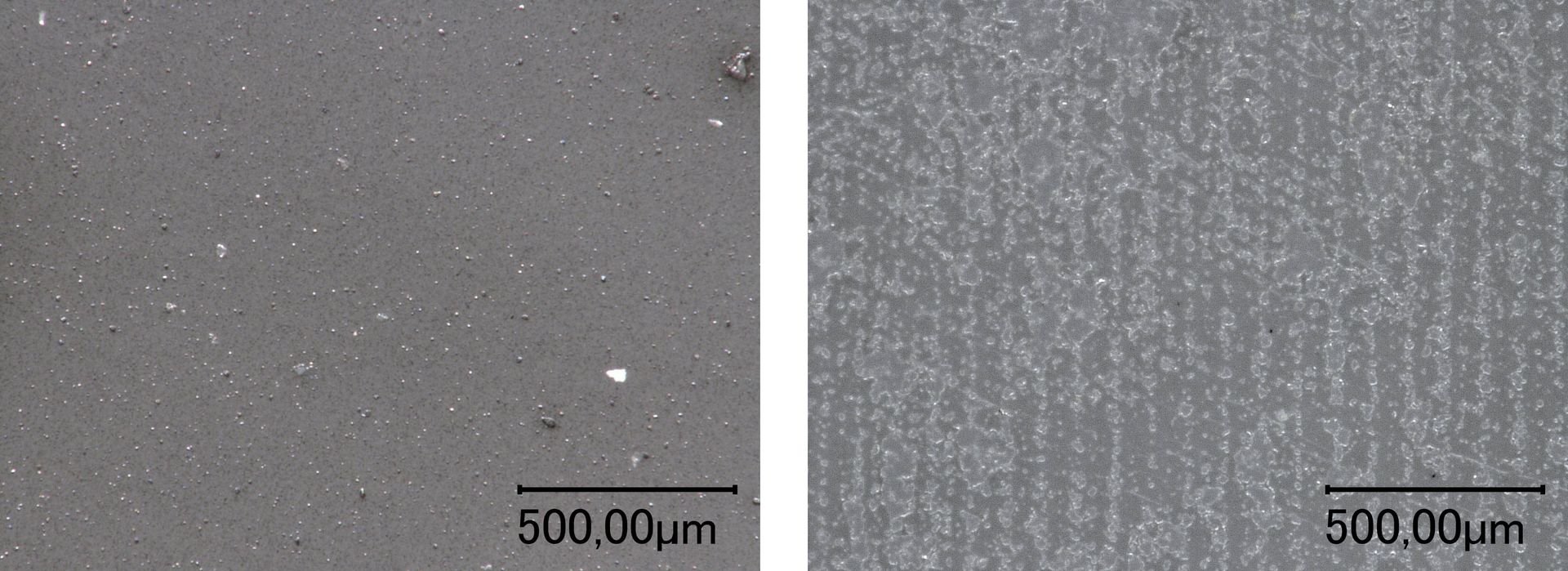

Chemical Surface Modification for Improving the Adhesion of Polymer Materials by means of IR Laser

Uncolored plastics that are difficult to bond (PE, PP, POM, PTFE) are chemically modified with the aid of an IR solid-state laser in such a way that they exhibit very good basic adhesive properties for subsequent bonding and coating. The basis are adhesion promoting formulations containing suitable polymers and IR-sensitizers as well as other additives, which are thermally activated and anchored by subsequent laser treatment after application and drying on the surface.

The following advantages are seen in contrast to conventional pretreatment techniques:

- Laser can activate even un-colored plastics.

- The activation (improving the adhesion of the background) exceeds the increase in surface roughness commonly known from lasers.

- The thermal load on the substrates is low.

- Due to the high spatial resolution of the laser irradiation (min. 50 micrometers), the surfaces to be pretreated can be processed very precisely without damaging adjacent structures.

- If required and/or if advantageous, the laser can simultaneously microstructure the surface to achieve additional adhesion improvement.

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48