UV Activation

The high energy of short-wave UVC radiation (< 200 nm) offers multiple innovative approaches for efficient surface modification under mild conditions and without application of aggressive or hazardous chemicals.

Our research is primarily focused on developing practical process solutions to improve adhesion or wetting properties of polymer materials, textiles or glass through treatment of their surfaces with UVC light under atmospheric conditions as well as extending the field of application of the UVC treatment by combining it with the use of precursors.

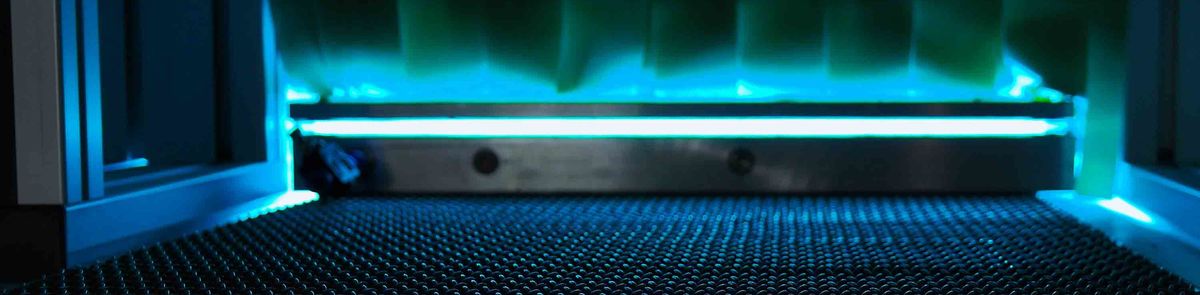

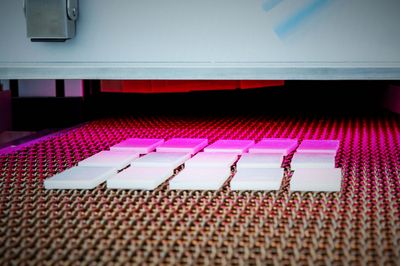

A versatile applicable and simple convertible experimental setup has been constructed, which can be used with different light sources and optionally as closed chamber or as open system in continuous operation. For performing the UVC treatment, air can be added or replaced by other gases (e.g. inert gas, nitrogen, precursor) if it required for the task or the material system. For developing and testing new methods as well as testing the method on new materials, various UVC sources with different emission wavelengths are available:

• Low-pressure mercury irradiation unit, 185 nm and 254 nm

• Xenon-xenon-2 excimer unit, 172 nm

• Argon/fluorine excimer laser, 193 nm

According to the respective task, the available technical and analytical equipment allows us to develop, test and demonstrate process solutions on behalf of customers. Examples of previous UVC process developments are methods for pretreatment of polymers and elastomers such as polypropylene, polyamide, fibre reinforced polymers, silicone and glass for adhesive bonding, coating, varnishing or even process developments for the pretreatment of synthetic textiles for their integration into composites with TPE or elastomer materials.

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48