Cleaning using Laser Technology

By treating surfaces with laser light, very different effects can be achieved depending on the material and process control. Surfaces can be cleaned, decoated, marked, structured, chemically modified and effectively activated for improved adhesion of paints and adhesives.

Decisive for achieving a specific treatment goal are process parameters that are optimally adjusted to the material and the purpose to be achieved.

For the development and testing of laser technologies for surface modification, we have a highly variable solid-state laser system.

Laser radiation is used to remove the light top coat and the brown primer down to the metal.

The focused laser beam removes the layers by evaporation. The degradation products are directly sucked off which minimizes contamination.

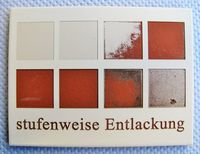

Several cleaning steps are shown in the figure. The number of treatment cycles increases from left to right and from the upper to the lower line, so that the light paint and brown primer are removed in individual steps and thin layers.

The stepwise paint removal can be operated with high local resolution by using laser technology.

The use of GRP tool shapes can cause damage to the tool surface. This damage can be partially corrected by mechanical removal and subsequent reconstruction of the repair area.

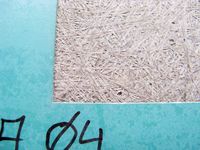

Laser radiation can also be used to remove the gelcoat layer and the modified mold-making resin prior to rebuilding the tool, whereby a precise, gentle and complete exposure of the first glass fiber mat layer can be achieved.

In the picture, the turquoise gelcoat layer and the modified mold-making resin were removed with the laser as a prerequisite for the subsequent repair.

Compared to conventional mechanical removal methods, the exposure of the glass fibers is very gentle on the material. The composite can therefore be rebuilt without major damage to the glass fiber layers. The use of an additional primer before rebuilding increases the bond strength at the repair site.

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48