Biologically Influenced Corrosion

Although corrosion is thought of as a process in which oxygen and water come into contact with a metal - aerobic corrosion, an indicative proportion of metal corrosion takes place in the complete absence of oxygen - aerobic corrosion. This can occur in iron or steels in an aqueous environment at low pH values ("hydrogen corrosion") or in the presence of sulfate ions and certain "sulfate-reducing" bacteria (SRB).

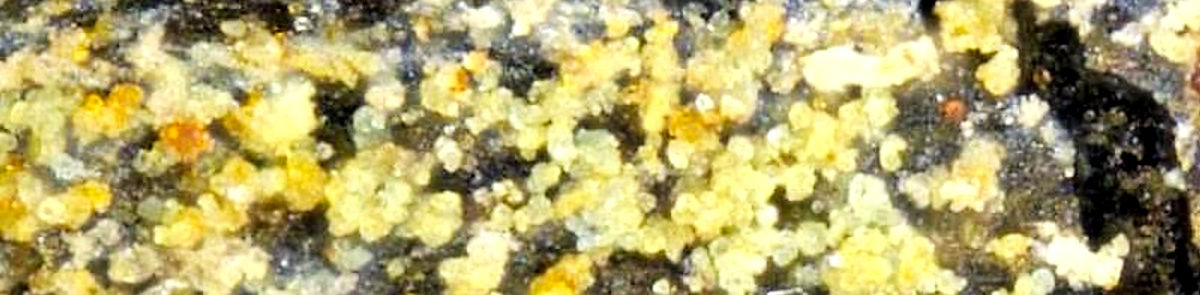

Iron alloys that have been corroded with the participation of sulfate reducers exhibit dark spots of iron(II) sulfide on their surface.

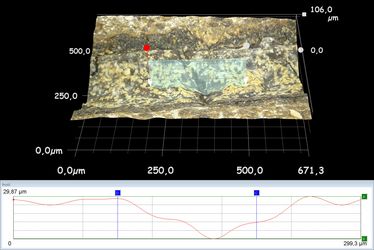

If the iron(II) sulfide is removed, an anodic deepening with bare iron appears. By examining the damaged area with a 3D microscope, the anodic indentation is visually detected and spatially measured.

Sulfate-reducing bacteria (SRB) accelerate the corrosion of steel up to 10 times more than aerobic (atmospheric) corrosion. In addition, this corrosion mechanism also attacks stainless steels usually well-protected by passivation.

As a result of this type of corrosion, high economic damage occurs above all in:

- Storage tanks and pipelines for crude oil and its products

- Port facilities

- Chemical plants

- Drinking water plants

Often the affected plants are not accessible for the necessary continuous cleaning. In these cases, a protective layer against biocorrosion is essential.

The development of such protective coatings must be specially designed for each case.

In addition to relevant experience in the development of such protective coatings of various types, the appropriate equipment for the production of these coating materials is available. However, a corresponding test is decisive. For this purpose, INNOVENT has developed a test with appropriate bacterial strains that is especially suitable for this type of corrosion. The usual test duration of 3 to 5 months is reduced to 1 month.

Dr. Joerg Leuthaeusser

Head of Department

Primer and Chemical Surface Treatment

e-mail

Phone: +49 3641 2825 48