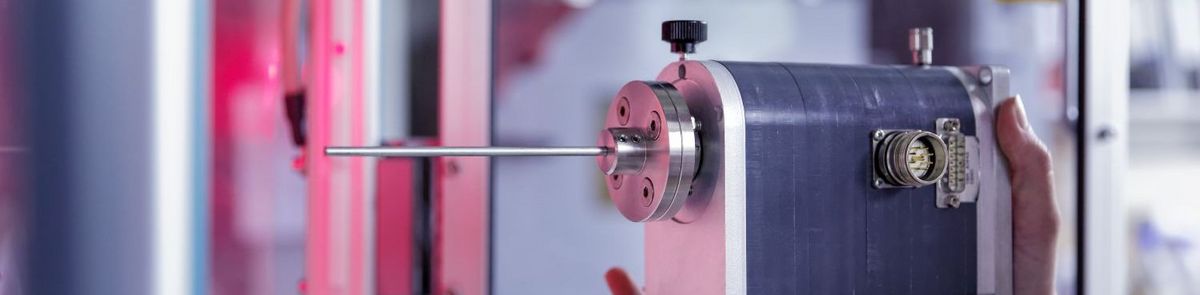

Electrospinning System

Technical Specification

- E-spintronic I and II

- Negative high voltage max. 100 V

- Fixed and CNC-controlled plate collector

- Drum, rod, rotary plate collector up to 2500 U / min

- Mono and double syringe pumps

- Single, coaxial and multiple nozzle systems

- Air-conditioned process room with adjustable temperature and relative humidity

- IR heat source

- Electrospraying setup

- Electro-melt spinning system (prototype)

- Positive / negative high voltage max. 100 kV

- Processing of extruded polymer strands

Applications

- Synthesis of nonwoven up to 400 cm2 in size consisting of micro- and nanofibers for medical applications or technical systems

- Nonwoven average 50 nm to 2.5 µm

- Processing of polymer solutions and melts

- Production of round and rectangular nonwovens, electro-spun porous tubes and other 3D shapes

- Synthesis of single-fiber and multi-fiber systems with single, coaxial and directional fibers

- Numerous polymers can be spun, e.g. polyurethanes, polyesters, poly-lactones, silicones, copolymers and various biopolymers

- Integration of various additives, e.g. bioactive substances, dyes and nanoparticles

- Incorporation of active substances and combinations of active substances for fiber-based drug delivery systems with controllable release

- Electrospraying for coating surfaces and test specimens

- Sol-gel coating on complex 3D specimens

Overview of Our Equipment

- Up-scaling Synthesis Laboratory

- Chemical Synthesis Laboratory

- Oxygen Generator

- Ozone Generator

- Pressure Reactor

- Microwave Synthesis System

- Freeze Drying System

- FT-IR

- UV-VIS-NIR

- NMR

- HPLC

- Flash MPLC/HPLC

- GPC

- Viscometer

- Texture Analyser

- Pycnometer

- Zeta Potential Measurements

- Biological Laboratory

- qPCR

- Microplate Reader

- Rotary Microtome

- Chemocam

- Laser Scanning Microscope

- Light Microscope

- Extruder

- Injection Molding Maschine

- Electrospinning

- Dispensing Robot

Manufacturer:

Erich Huber GmbH, Gernlinden, Germany

Electro Melt Spinning System: in-house design INNOVENT

Model:

E-Spintronic I & II