PACVD – Plasma Assisted Chemical Vapour Deposition

Plasma polymerization (PACVD) is a chemical vapour deposition method which can be characterized by a chemical reaction of gaseous precursor materials resulting in the growth of thin films on work piece surfaces. This method can be carried out with the assistance of a high-frequency plasma. In this case the energy necessary for the chemical reaction is supplied by high energetic electrons. This results in an only moderate temperature increase of the work pieces. The deposition system itself consists of a vacuum chamber including two planar electrodes, one of those is r.f. coupled to the power supply. Thus, thin planar substrates up to a diameter of 20 cm can be coated without problems.

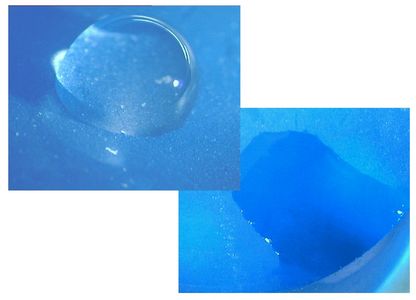

The deposited functional layers or the plasma treatment itself can lead to new surface properties like high wettability or high hydrophobicity, scratch resistance or a higher adhesiveness.

Applications

Examples for applications:

- Creation of hydrophilic surfaces e.g. for materials used in medical engineering

- Activation on polymers for lacquering and gluing

- Surface cleaning in an oxygen-containing plasma

References:

A. Pfuch, A. Heft, R. Weidl, K. Lang; „Characterization of SiO2 thin films prepared by plasma-activated chemical vapour deposition“, Surf. Coat. Technol., v.201, 2006, p.189-196