Crystal Growth Methods

Epitaxial films are fabricated by liquid phase epitaxy technique (LPE) from high temperature solutions and single crystals by single crystal growth techniques.

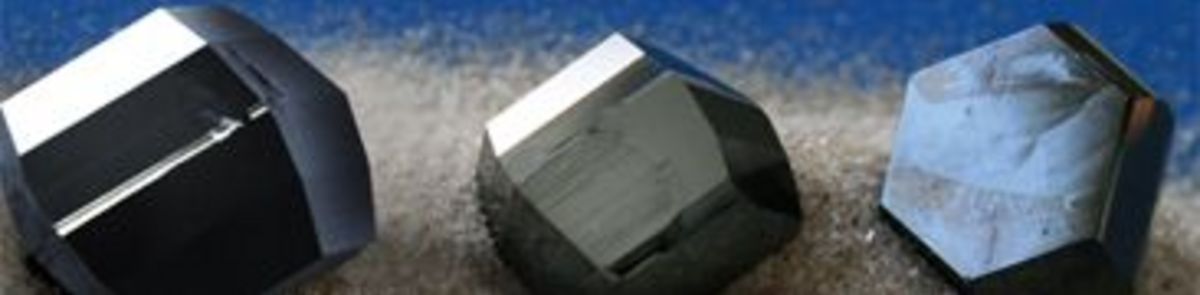

Cooling Process with Bottom Cooling (Spontaneous Nucleation)

For the growth of high quality single crystals, which cannot be fabricated from their own melt, methods of solution growth which using aqueous solutions or melt solutions (high-temperature solutions) are used.

Crystallization can take place spontaneously or by growth on a given seed crystal. The cooling process used leads to a spontaneous crystallization of several crystals in the solution, whereby the crystallization preferably takes place at the crucible bottom using local bottom cooling and a suitable temperature gradient.

The "Accelerated Crucible Rotation Technique" (ACRT) is used to homogenize the solution and thus ensure a homogeneous chemical composition over the entire crystal volume as well as a minimization of solvent incorporation.

With this process we obtain not only commercially processable crystal material of high perfection, but also seed crystals for the crystallisation of large single crystals (see TSSG process).

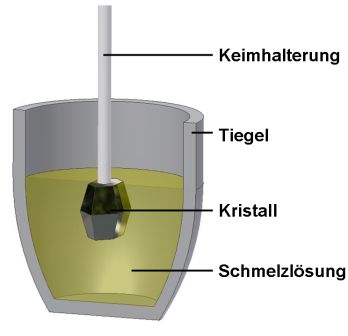

Top Seeded Solution Growth (TSSG) Technique (Seed Based)

If seed crystals are used, crystallization can be achieved by immersing them in a supersaturated solution. This process corresponds to the Czochralski technique (pulling of the seed crystal positioned on the surface during growth) and the Nacken-Kyropoulos process (growth of a seed crystal completely immersed in the solution volume) used in melts.

The TSSG technique can be applied to both the gradient method (with depot material and temperature gradient) and the cooling method (of a saturated melt solution). The former is essentially used for compounds containing substituents/dopants, while the latter is used for unsubstituted compounds.

In order to homogenize the solution and to control the growth, a seed crystal rotation is usually carried out in the solution and for the gradient method an additional pulling movement out of the solution is applied.

With this process it is possible to obtain high quality and large single crystals which have not been subjected to stresses in the solidifying solution due to the removal from the solution before the cooling process starts. Usually the quality and yield of TSSG grown crystals is higher than for spontaneously grown crystals after the cooling process.

Liquid Phase Epitaxy

The liquid phase epitaxy (LPE) process is used to fabricate single crystalline films of high crystal quality with film thicknesses in the µm range. The aim is to grow materials in solution on a single crystalline substrate with comparable lattice parameters in accordance with crystallographic laws.

Film growth is achieved by bringing a stationary or rotating substrate of defined crystallographic orientation into contact with a supersaturated solution and when the desired film thickness is reached, the sample is drawn from the solution.

The main advantages of the LPE technology compared to other deposition processes are:

- Realization of film thicknesses between 10 nm and 100 µm while maintaining high structural perfection over the entire layer thickness

- Growth of thermodynamically stable phase with or near ideal stoichiometry

- Formation of extremely smooth surfaces possible

- Simple and cost-effective technology

The limits of the technology:

- Limited availability of lattice-adapted single crystalline substrate materials, which must also be chemically inert to the solutions used

Process Engineering

TSSG Crystal Growing Systems

- Resistance-heated vertical multi-zone tube furnaces

- Operating temperatures from room temperature to maximum 1300°C

- Normal pressure and/or adjustable process gas flow rate (N2, Ar, O2,)

- Crystal pulling speed min. 0.001 mm/h

- Crystal rotation speed ± 200 rpm (programmable change of rotation direction)

- Crucible rotation with ACRT technology for crucible diameters up to 70 mm max.

- SPS device control / process visualization

- Crystal weighing option

1-Inch and 3-Inch LPE Deposition Systems

- Resistance-heated vertical multi-zone tube furnaces

- Operating temperatures from room temperature to maximum 1300°C

- Normal pressure and/or adjustable process gas flow rate (N2, Ar, O2)

- Substrate rotation speed up to 200 rpm (programmable change of rotation direction)

- Centrifugal rotation up to 1200 rpm

- Crucible rotation with ACRT technology for crucible diameters up to 110 mm max.

- SPS device control / process visualisation