Synthesis Optimization

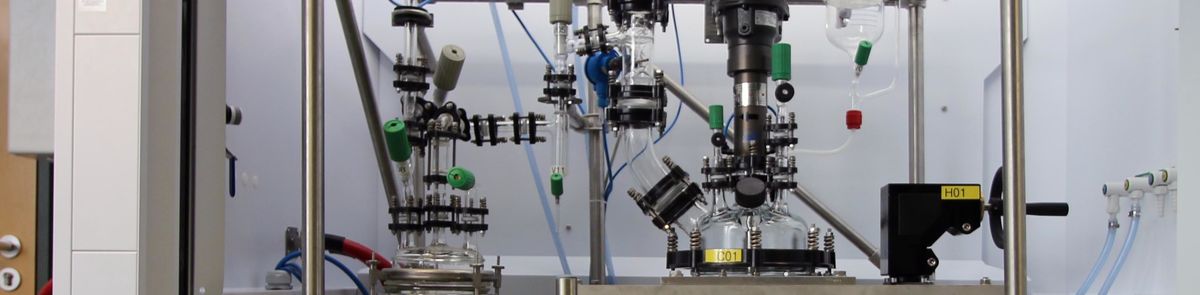

For the scale-up of a laboratory-developed synthesis, process steps must be optimized, adapted to technical conditions and sometimes even newly designed. For further investigations, it is often necessary to individually produce test samples in quantities ranging from a few hundred grams to a few kilograms. In order to meet the requirements of our project partners and customers, we at INNOVENT have set up a pilot laboratory for scale-up, process optimization and adaptation (SPA laboratory).

The following equipment is available:

- Systems engineering with stainless steel and glass reactors, stirrers and filtration technology for syntheses on a kilogram scale

- Inert gas (N₂, Ar) and vacuum technology

- Operating temperature -40 to +150 °C

- Working pressure up to 1,5 bar

- Autoclaves for pressure reactions up to 200 bar

- Large rotary evaporator

- Freeze dryer

- Preparative flash chromatography and HPLC

- Process control and automatic data acquisition

We would be pleased to take over your custom synthesis. Detailed information about the synthesizable compounds can be found here.