Thermal Evaporation

The thermal evaporation allows a relatively uncomplicated application of thin layers on almost any surfaces of high-vacuum-steady materials. It occurs under high-vacuum conditions by resistance heating of the material that should be evaporated. The palette of the materials that can be evaporated is very big and is limited by the melting point of the tungsten material used as a heating filament.

Two separate heating filaments are built into the evaporation chamber (50 L). So, two different materials can be evaporated simultaneously or one after another without interrupting the vacuum conditions. The integrated glow discharge equipment allows a pre-treatment and a surface cleaning of the material that should be evaporated. This will be realized by the ignition of a low pressure plasma under defined gas conditions. In special cases, such a pre-treatment allows not till then a good adhesion of certain layers on the substrates.

The film thickness is controlled by a film thickness monitoring using an oscillating crystal technique. To guarantee a homogenous film thickness the workpieces can be rotated in two dimensions.

Customer specified setups within the vacuum chamber can be realized due to free or unused flanges at the chamber. Limited possibilities for patterning of samples by using a shadow mask technique are given.

Applications

Examples for applications:

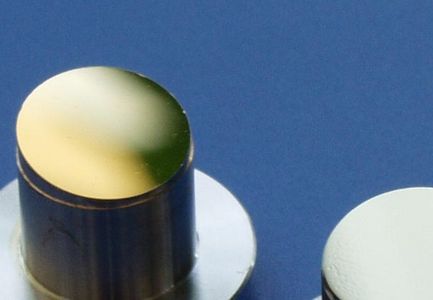

- Reflective coatings (aluminium, gold)

- Surface plasma cleaning