Innovative User Project (INNovative Anwender-Projekte)

In an Innovative User Project (INNovatives Anwender-Projekt - INNAP), INNOVENT combines development work on novel topics and technologies of surface treatment, as well as composite problems or coating technology for interested companies. The project expenses are jointly financed by the participating companies, with a fixed contribution without the use of public funds.

The respective project work plan is coordinated with the project participants, which includes company-relevant problems. According to the project agreement, the plan and test results are exclusively accessible to the participating companies. If necessary, they are provided in an anonymised form, and are subject to confidentiality.

Participating companies are thus given quick, uncomplicated and exclusive access to innovative technologies, scientific-technical know-how and new methodological approaches. This allows for improved access and use of their potential, for company-specific tasks or preliminary topics.

The project type INNAP offers:

- Low cost: Participants share the project financing.

- High application relevance: By taking up application-relevant problems of the participating companies, the usability of the project results for company-specific applications and transfers is ensured.

- Confidentiality: The documentation of the project work and results is carried out under confidentiality of company knowledge, and company-specific know-how. In addition to the services agreed in the project, individual agreements can be made with participating companies.

- Low personnel deployment at participating companies: INNOVENT is responsible for the organisational project management, test execution and documentation. The personnel expenditure is determined by the companies themselves, and can be reduced according to the participation in the project events.

- Minimal technical effort and time saving: INNOVENT uses practical experimental technology and existing scientific and technical know-how, to carry out the project. Expenditure for research or experimental set-ups is eliminated. The project results are made available to the participants exclusively and continuously during the project.

- Extended scope of data: Problems of several project participants are processed and compiled in parallel.

- Further training/staff qualification: The cooperation in the project, as well as the project meetings (approx. 2-3 per project), enables the exchange of knowledge, experiences and contacts.

Further explanations can be found in the INNAP Special Terms of Contract.

Related Downloads

Surface Treatment with UVC Light

Pretreatment and Functionalization of Plastic and Elastomer Surfaces

Contact: Dr. Jörg Leuthäußer

Processing period: November 2018 to July 2019

Flyer "Oberflächenbehandlung mit UVC-Licht"

This project was carried out to obtain information about a possible effectiveness of surface treatment with short-wave UVC light to improve the adhesion or wettability of plastics or elastomers used in industrial practice. In addition, methodological approaches and parameter influences were compared by using the broader data pool.

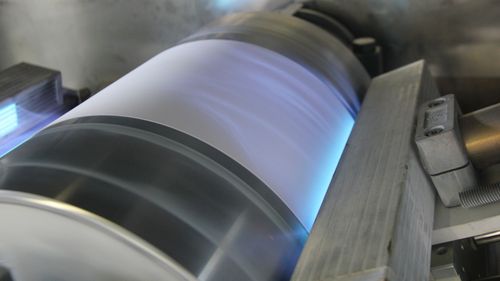

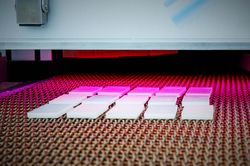

During this project, a series of orienting tests regarding the surface treatment of plastics and elastomers with short-wave UVC light in the range below 200 nm were conducted. For this purpose, two practically relevant UVC light sources were applied (low-pressure mercury lamp system, xenon-xenon excimer lamp). The results of the UVC treatment were evaluated by measuring static contact angles and determining the surface energies as well as by preparing and testing representative adhesive composites.

For all materials brought into the project by the participants, there are results from comparative experiments on UVC surface treatment within the parameter range defined for the project. Achieved wetting or adhesion-enhancing effects were characterized in more detail by additional UVC treatment tests and material-specific investigations.

Further projects of the INNAP format in extension of the subject area of surface treatment with short-wave UVC light are planned.

Highly Resistant Bonding of Stainless Steels

Pretreatment and Adhesive Bonding of Corrosion Susceptible Steels

Contact: Dr. Jörg Leuthäußer

Processing period: February to November 2019

Flyer "Hochbeständiges Kleben von Edelstählen"

The aim of the project was to evaluate the potential of different silicatization processes in combination with silanes for the production of highly resistant stainless steel adhesive composites.

During the project, a series of tests were carried out in which material as well as surface condition on the one hand and adhesion-enhancing pretreatment on the other hand were varied. The evaluation of the pretreatment success was based on the tensile shear strength.

The results are available on:

- Performance and long-term efficiency of the various silicatization processes depending on the initial state of the surface, especially under cyclical hydrolysis load in an autoclave

- The efficiency of different adhesive silanes and their influence on the storage life of the treated surfaces

- As well as the relevant parameters for achieving a robust adhesive bonding.

The research results of the general part were also integrated into the investigations of the practice-relevant material and adhesive combinations of the participating companies.

Further projects of the INNAP format to expand the topic area of silicatization for load-stable adhesion improvement of composite relevant metals are planned.