Cold Plasma Spraying

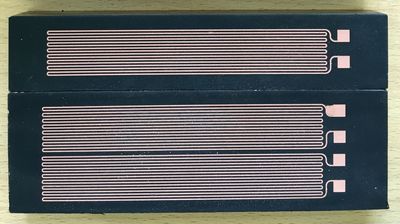

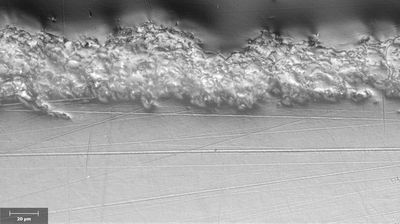

In addition to the APPCVD processes, the so-called plasma spraying processes have been available for many years. Using thermal plasmas with gas temperatures of sometimes more than 10000 K and with the addition of suitable powders (or suspensions, liquids), spray coatings of several micrometers thickness can be applied to thermally stable surfaces. Such plasma spraying processes can be divided into a whole family of thermal spraying processes for the production of metallic or ceramic coatings, in addition to the arc spraying, flame spraying or also the HVOF spraying processes. Although a large number of functional coatings can be produced with the classical plasma spraying process and the process has a broad industrial application, there is a decisive disadvantage: the limitation to sufficiently thermally resistant workpiece surfaces. In order to overcome these disadvantages, first investigations in the field of so-called cold plasma spraying were carried out in Germany about ten years ago, where functional coatings could be applied even on thermally unstable surfaces with the help of "cold" - in the sense of non-thermal - jet plasmas and by injecting suitable powders into the jet plasma.

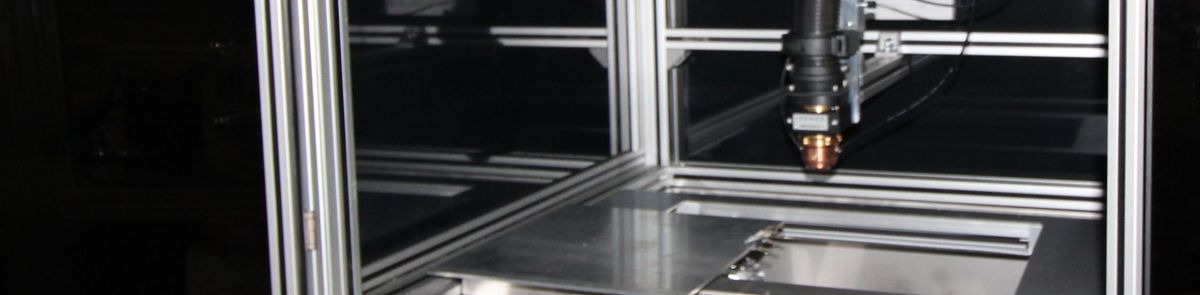

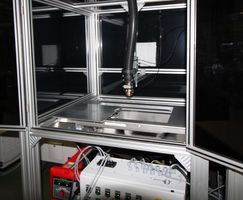

INNOVENT has invested in 2019 in appropriate plasma and powder feeding technology and is currently developing the technological basis for applying metallic and ceramic thick films to various, even temperature-sensitive materials.