Static Domain Visualization of Electrical Steel Sheets

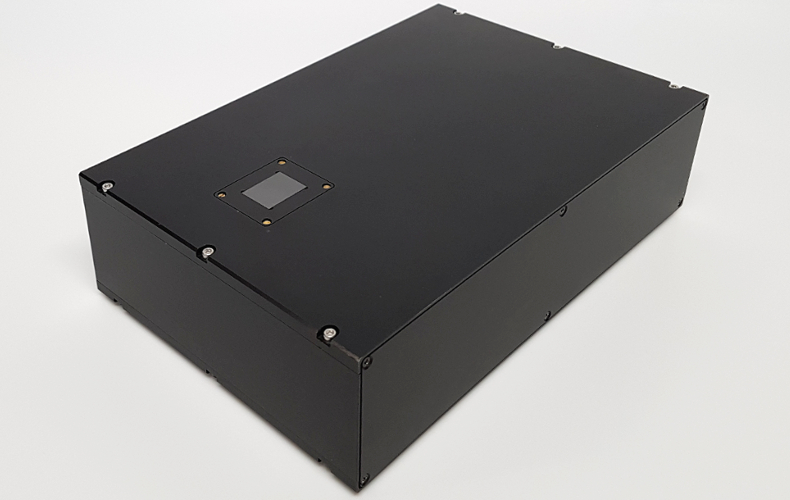

The camera based CMOS-MagView system is a testing device used for visualizing magnetic structures. Based on magneto-optical sensor technology, the imaging process permits rapid domain observation of electrical steel (SiFe alloys). With the associated application software, the analysis of the magnetic domain structure can be conveniently performed using magneto-optical images.

With the CMOS-MagView system, the domain structure in the statically magnetized state, can be observed and documented. The following properties of electrical steel sheets can be investigated:

- Domain structure

- Grain structure

- Grain sizes

- Crystallographic orientation of the grains in the plane

- Local defects

- Domain behavior during remagnetization

The included software of the CMOS-MagView system contains all necessary basic functions for image acquisition, display, analysis and storage. For example, the software offers the following basic functions:

- Ready-to-use software with default setting

- Single frame and video function

- > 1 magnetic field image per second

- Image averaging for noise reduction

- Differential image technique

- In-situ image contrasts

- Default settings (standard, user-specific)

- Archiving / Export / Import

- Geometry dependent field analyses

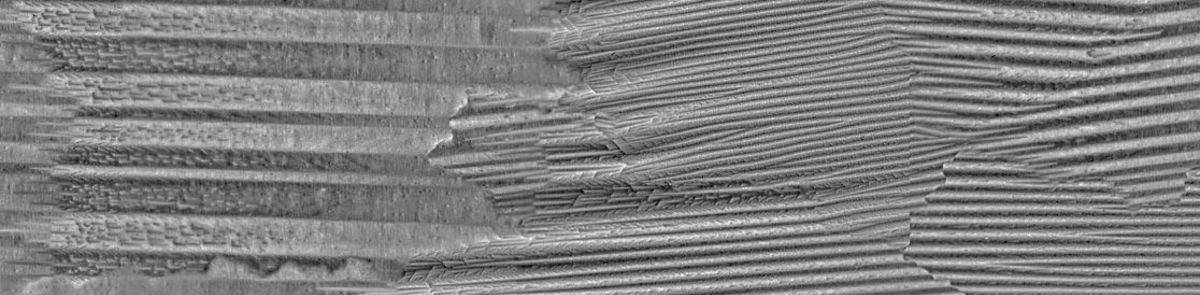

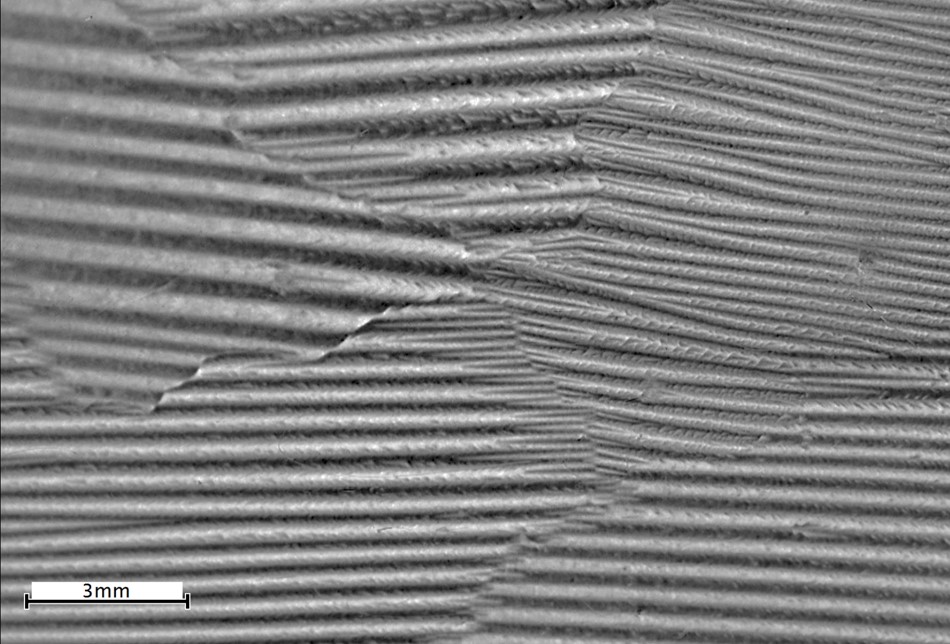

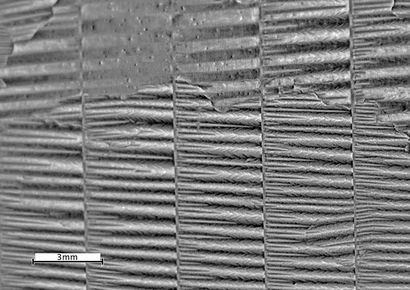

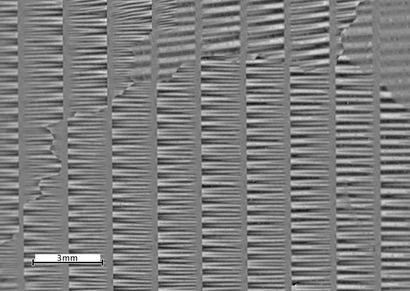

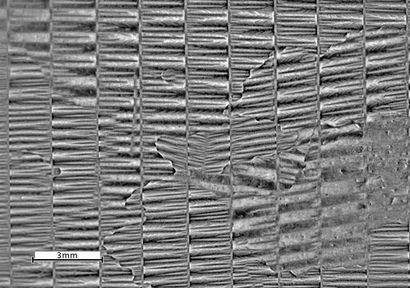

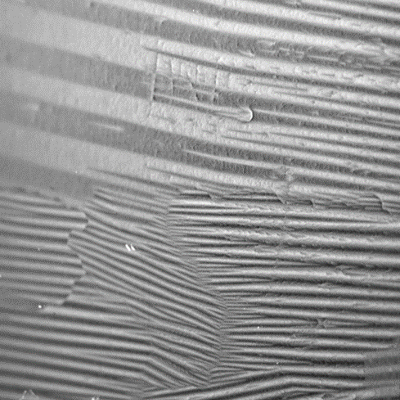

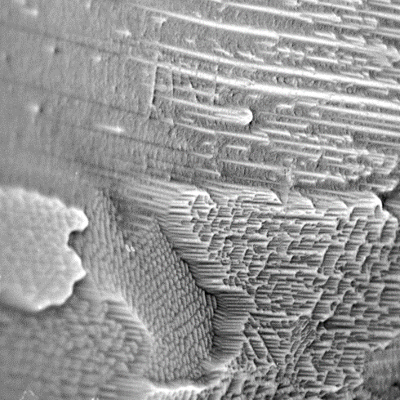

Domain structures of different sizes of grain-oriented electrical steel sheets (GO, IWS) after domain refinement by laser treatment

GO sample (IWS) with laser structuring (left: homogeneous, right: inhomogeneous)

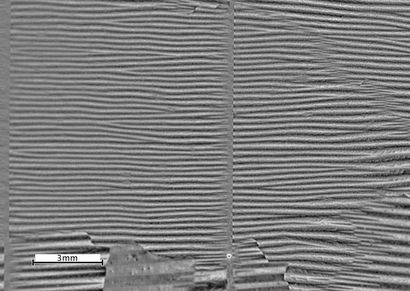

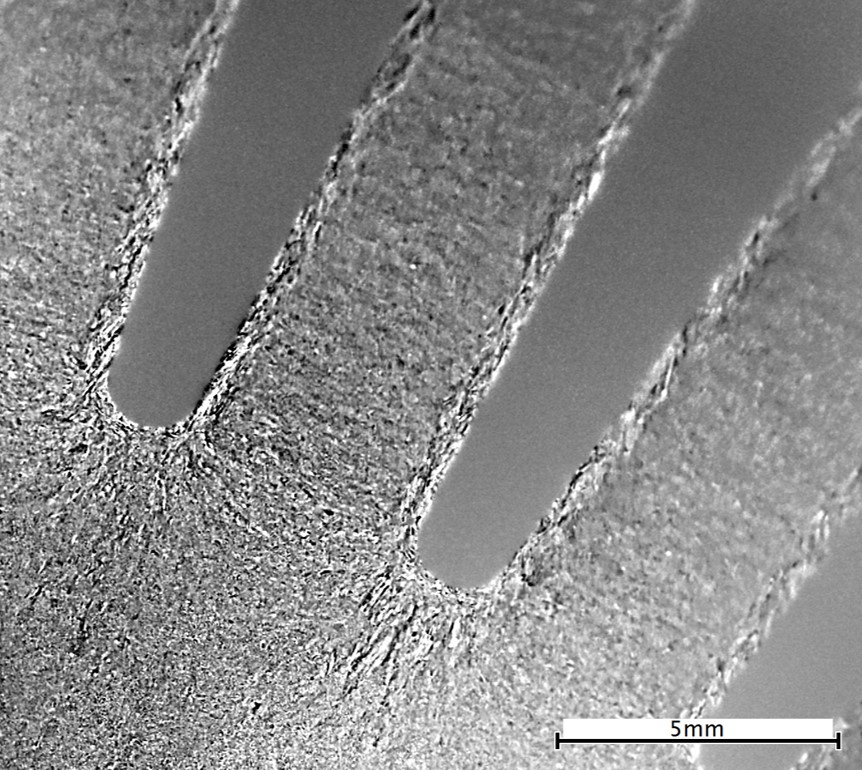

Domain structure of GO electrical steel sheet, in the initial state (left) and with induced flux (right)

Dynamic Domain Visualization of Electrical Steel Sheets

The Domain Tester has been specially developed for the effective investigation of the domains of electrical steel sheets (SiFe alloys) under alternating field conditions. The grains of electrical steel sheets form different magnetic domains. Depending on their crystallographic orientation, different types of domains arise, which are characteristic for certain remagnetization losses.

With the Domain Tester, the domain structure can be observed and documented statically as well as dynamically (during the remagnetization). The following properties of electrical steel sheets can be investigated:

- Domain structure

- Grain structure

- Grain sizes

- Crystallographic orientation of the grains in the plane

- Local defects

- Domain behavior during remagnetization

The big advantage is that time consuming sample preparation is no longer necessary. The electrical steel sheets can be examined non-destructively without having to mechanically remove the insulation layer and to polish the surface. Thus, in contrast to Kerr microscopy and MPI (magnetic particle inspection), a fast and high-resolution method is available for investigating the magnetic properties of electrical steel.

| Active MO sensor surface: | 18 x 13 mm² |

| Resolution: | 1 Pixel = 14 µm |

| Image acquisition frequency during dynamic testing: | 8 kHz |

| Video sequence (output): | MP4 format, 30 s at 60 frames / s (slow motion) |

| Alternating field frequency: | up to 400 Hz (yoke-supported), sinusoidal, triangular |

| Number of images per individual period: | 160 images with AC field at 50 Hz |

| Manufacturer of the test specimen: | thyssenkrupp |